In today’s fast-paced manufacturing world, every second counts. From material handling to final packaging, efficiency and precision can make or break a production line. That’s why smart automation has become the backbone of modern industries — and at the heart of this automation lies one critical system: the conveyor.

Bandma, a leader in industrial packaging automation, has taken conveyor technology to the next level. With its customized conveyor solutions, Bandma helps manufacturers design production lines that are faster, smoother, and perfectly aligned with their specific operational needs.

Why Conveyors Are the Backbone of Modern Manufacturing

Conveyors play a vital role in ensuring seamless product movement across various stages of manufacturing from raw material input to packaging and dispatch.

A well-designed conveyor system reduces manual handling, increases efficiency, and ensures a consistent flow of materials. However, not all production lines are the same. Every industry has unique requirements different product sizes, speeds, layouts, and operational challenges.

This is where Bandma’s customized conveyors come in built to adapt to your plant’s workflow, space, and production goals.

The Bandma Edge: Customization That Delivers

Bandma doesn’t believe in one-size-fits-all. Every conveyor solution is tailor-made to optimize movement, save time, and enhance productivity.

Here’s what makes Bandma’s customized conveyors stand out:

✅ Tailor-Made Design

From straight belt conveyors to complex modular systems with multiple transfer points, Bandma designs conveyors that perfectly fit your plant layout and workflow.

✅ Multi-Industry Compatibility

Whether you’re in FMCG, food & beverage, pharmaceuticals, logistics, or automotive, Bandma’s engineering team creates conveyors that meet your exact requirements.

✅ Material Flexibility

Choose from stainless steel, mild steel, or modular plastic belts depending on your product type, environment, and hygiene needs.

✅ Automation-Ready

Bandma’s conveyors integrate seamlessly with carton sealers, strapping machines, case erectors, and labeling systems, creating a complete packaging automation line.

✅ Built for Durability

Engineered with heavy-duty components, Bandma conveyors ensure long-term reliability, even under continuous operation.

Types of Customized Conveyors by Bandma

Bandma offers a wide range of conveyors, each designed for specific applications:

Belt Conveyors – Ideal for smooth product transfer in packaging and assembly lines.

Roller Conveyors – Perfect for cartons, cases, or heavier products.

Incline/Decline Conveyors – Designed to transport goods between different levels efficiently.

Modular Chain Conveyors – For flexible layouts and easy maintenance.

Turntable Conveyors – For space-saving direction changes.

Z-Type & L-Type Conveyors – To handle elevation-based material movement with ease.

Each conveyor type can be custom-sized, automated, and integrated with other Bandma systems for a fully connected workflow.

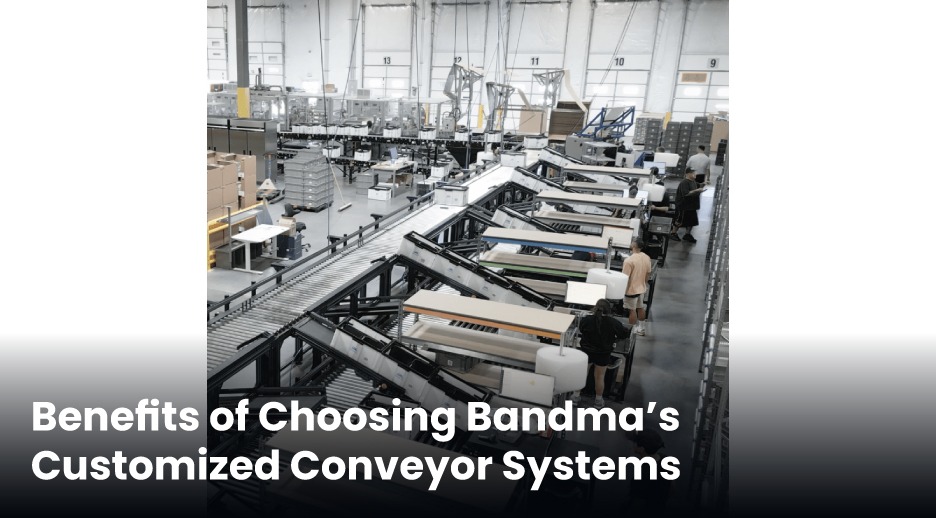

Benefits of Choosing Bandma’s Customized Conveyor Systems

- Higher Productivity

By automating material handling, you reduce idle time and increase production speed achieving consistent, round-the-clock performance. - Space Optimization

Bandma designs conveyors that fit your exact floor layout, ensuring maximum efficiency in limited space. - Reduced Labor & Cost

Automated conveyors minimize the need for manual handling, improving safety while lowering operational costs. - Smarter Integration

Conveyors are built to communicate with other machines via PLCs, sensors, and IoT systems forming a smart, synchronized packaging line. - Long-Term Reliability

Precision engineering and robust construction ensure your conveyor runs smoothly for years with minimal maintenance.

Applications Across Industries

Bandma’s customized conveyor solutions serve a wide range of industries, including:

Food & Beverage – Hygienic conveyors for packaging bottles, cans, or cartons.

Pharmaceuticals – Cleanroom-grade conveyors for product handling and labeling.

E-Commerce & Logistics – High-speed conveyor systems for sorting and dispatching.

Consumer Goods – Smooth product flow for packaging and assembly lines.

Automotive & Engineering – Heavy-duty conveyors for parts handling and machine feeding.

No matter the industry, Bandma ensures each conveyor system enhances workflow and production output.

Smart Automation and Future-Ready Features

As industries embrace Industry 4.0, Bandma’s conveyors come equipped with smart control systems for real-time performance tracking and predictive maintenance.

Key innovations include:

IoT connectivity for data-driven decision-making.

Variable speed drives for flexible production control.

Automatic start/stop sensors for energy savings.

Safety interlocks and emergency stop systems for worker protection.

These smart features make Bandma’s conveyors not just efficient but intelligent, adaptive, and future-ready.

Why Manufacturers Trust Bandma

Over the years, Bandma has earned the trust of manufacturers across India and beyond by delivering engineering excellence, customization, and dependable service.

From initial consultation and design to installation and after-sales support, Bandma provides end-to-end conveyor solutions that simplify operations and maximize ROI.

Each project begins with understanding the client’s workflow, then designing a conveyor system that optimizes every movement, reduces downtime, and enhances productivity.

Conclusion

In an age where efficiency defines success, Bandma’s Customized Conveyor Solutions give manufacturers the power to transform their production lines.

With tailor-made designs, advanced automation, and smart integration, Bandma’s conveyors ensure smooth product movement, reduced labor dependency, and consistent high performance.

From packaging plants to manufacturing floors, Bandma is redefining motion, one customized conveyor at a time.

Because in the world of industrial automation, Bandma keeps your production moving forward.