In modern manufacturing, precision and speed define success. Every hole, thread, and component needs to be crafted with perfect accuracy to ensure product quality and performance. That’s where taping machines play a crucial role.

From their early manual designs to today’s smart, automated systems, taping machines have undergone a remarkable evolution. Brands like Bandma are now leading this transformation offering high-performance taping solutions that combine engineering precision, digital automation, and unmatched reliability.

Let’s break down everything you need to know about taping machines and how automation is reshaping their role in industrial production.

1. What Is a Taping Machine?

A taping machine is a mechanical device used to cut internal threads (also called “taps”) into a drilled hole. This allows screws or bolts to fit securely, ensuring strong, reliable assembly in manufactured products.

Whether you’re producing automotive components, machinery parts, or consumer goods, tapping machines are essential for creating threaded holes with accuracy and repeatability.

Bandma’s range of automatic and semi-automatic taping machines are engineered to meet high-volume industrial requirements ensuring consistency, durability, and operational efficiency.

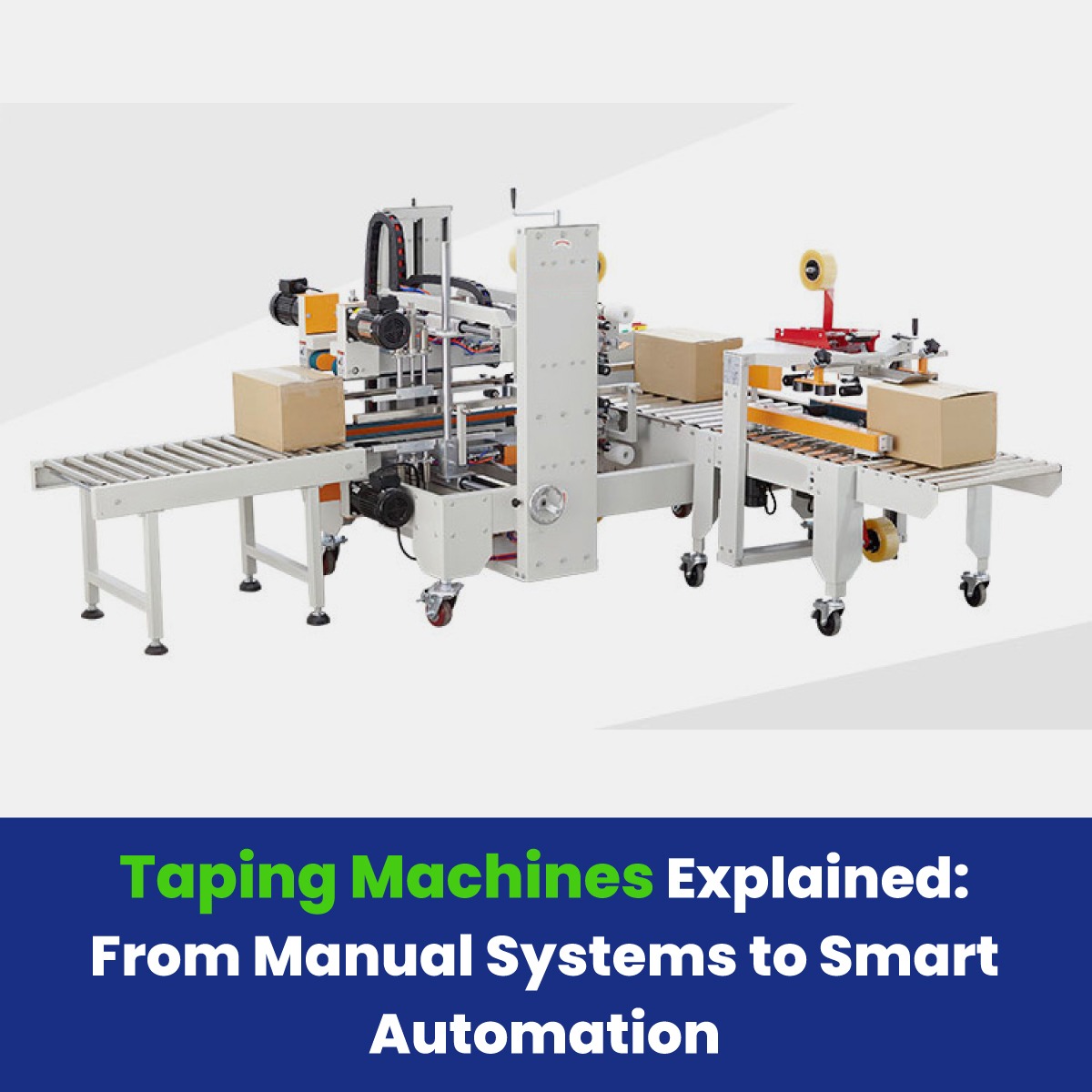

2. The Evolution: From Manual Taping to Smart Automation

Manual Taping Machines

Traditional taping was performed manually using handheld tools or basic mechanical setups. While functional, manual systems were time-consuming and prone to inconsistencies, especially in mass production.

Semi-Automatic Taping Machines

The next generation introduced semi-automatic systems that offered better speed and precision. Operators could control torque and direction, reducing errors and improving productivity.

Fully Automatic and Smart Taping Systems

Today, automation and digital control have revolutionized the process. Bandma’s smart tapping machines come equipped with advanced servo motors, PLC controllers, and digital torque monitoring systems, delivering unmatched precision with minimal human intervention.

These intelligent systems can adjust speed, depth, and pressure automatically ensuring consistent threading quality across thousands of components.

3. How a Taping Machine Works

A typical taping process involves:

- Positioning: The machine aligns the tool with the drilled hole.

- Feeding: The tap tool enters the material at a controlled speed.

- Thread Cutting: Internal threads are cut with precision under monitored torque.

- Reverse Motion: The tap retracts automatically once the thread depth is reached.

Bandma’s machines automate each of these steps, using digital control systems to monitor torque, depth, and feed rate in real-time — resulting in perfect threads every cycle.

4. Benefits of Using Bandma Taping Machines

1. Precision and Consistency

Every thread is cut to exact dimensions. Bandma’s servo-controlled motors ensure precision and uniformity in every part.

2. Increased Productivity

Automated taping significantly reduces cycle time, allowing manufacturers to handle higher volumes with fewer operators.

3. Reduced Human Error

By automating the taping process, Bandma machines eliminate inconsistencies caused by fatigue or manual variation.

4. Energy and Cost Efficiency

With optimized power consumption and reduced material waste, these machines deliver higher output with lower operational costs.

5. Safety and Ease of Use

Modern taping systems come with safety interlocks, automatic shutdown features, and user-friendly interfaces making them safe and easy to operate.

5. Applications Across Industries

Taping machines are vital in almost every industrial sector that involves metal or plastic fabrication. Bandma’s taping systems are widely used in:

- Automotive Manufacturing: Threading parts like engine blocks, brake components, and chassis parts.

- Electrical and Electronics: Taping small, high-precision components and housings.

- Aerospace: Producing threaded parts with tight tolerance levels.

- Machinery & Engineering: Creating threaded holes in mechanical parts and industrial assemblies.

- Consumer Goods: For metal and plastic parts that require secure fasteners.

Bandma’s taping machines are available in customizable configurations to meet the specific requirements of each industry from small-scale workshops to large production facilities.

6. Smart Automation and Industry 4.0 Integration

Bandma is not just keeping pace with technology it’s setting the pace. Its next-generation tapping machines are equipped with smart features like:

- IoT-based performance monitoring

- Predictive maintenance alerts

- Digital torque and depth control

- Programmable speed settings

- Real-time production analytics

These features allow manufacturers to track productivity, optimize settings, and ensure minimal downtime. The result? Smarter, faster, and more reliable operations that meet Industry 4.0 standards.

7. Bandma’s Edge in Taping Technology

What truly sets Bandma apart is its commitment to precision, reliability, and service.

Each taping machine is designed with robust construction, high-efficiency drives, and modular components that allow easy upgrades and integration. Bandma’s engineering team works closely with clients to customize machines based on specific production goals making it a trusted partner for industries across India and abroad.

From compact bench-type tappers to fully automated taping lines, Bandma’s portfolio covers every production scale and application.

8. The Future of Taping Technology

The future of tapping is intelligent, adaptive, and sustainable and Bandma is already leading that transformation.

Expect to see taping machines with AI-driven process optimization, smart torque sensors, and integration with robotic handling systems. These innovations will not only improve productivity but also reduce energy consumption and operational waste.

Bandma’s focus on “Smart Engineering for Smarter Manufacturing” continues to shape the next era of industrial automation.

Conclusion

From manual setups to fully automated precision systems, taping technology has evolved into a cornerstone of modern manufacturing.

With Bandma’s advanced taping machines, industries gain access to unmatched accuracy, reliability, and performance helping them meet today’s production challenges and prepare for tomorrow’s opportunities.

In an age where every second counts and every micron matters, Bandma ensures your taping process is not just efficient it’s exceptional.