Efficiency and accuracy are essential in the fast-paced world of commercial and industrial packaging. Table Top Strapping Machines stand out as a little yet effective instrument among the many that have transformed packing procedures. These devices offer a simplified and economical method of package security, which makes them essential in sectors like retail and logistics.

This blog explains the workings, benefits, and uses of tabletop strapping machines, illuminating why companies all over the world are increasingly choosing them.

What Are Table Top Strapping Machines?

A table top strapping machine is a small device used to secure products for storage or transit by wrapping them in a plastic strap, usually made of polyester or polypropylene. By ensuring that packages stay intact, the system lowers the possibility of damage or manipulation. Its tabletop design maintains high levels of efficiency, making it perfect for workspaces with limited space.

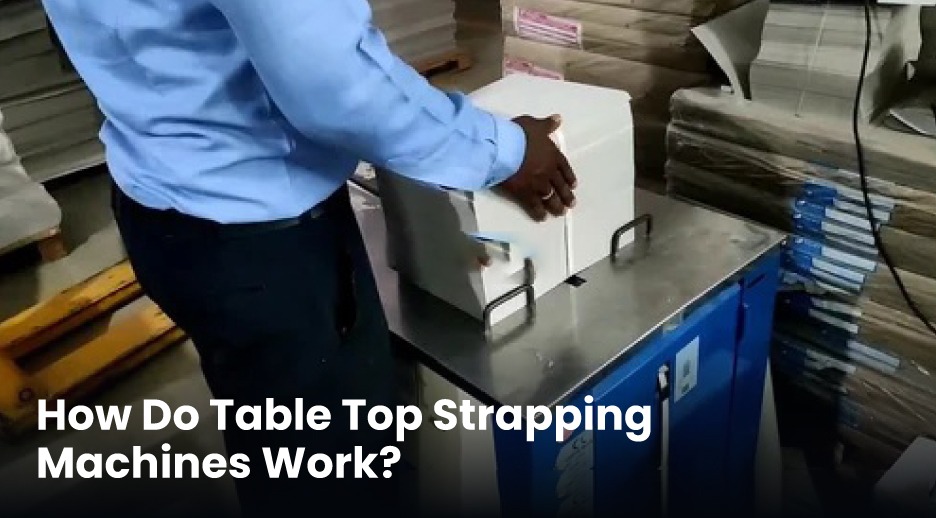

How Do Table Top Strapping Machines Work?

These machines operate on a simple yet effective mechanism:

- Strap Loading

The machine is filled with the strapping material. For rapid and simple strap replacement, modern machines frequently use an auto-feed mechanism. - Package Placement

On the table is the object or cargo that has to be strapped. After wrapping the strap around the package, the operator slides the strap end into the slot of the machine.. - Tension and Sealing

To ensure a snug fit, the machine tightens the strap around the box. The package is then neatly secured once the strap is cut and sealed. - Ready for the Next Package

The machine allows for continuous operation by preparing the strap for the subsequent package when the process is finished.

Key Features of Table Top Strapping Machines

- Compact Design

These machines are perfect for companies with limited space, like retail stores or small warehouses, because of their compact size. - Ease of Use

These devices are easy to use and frequently require no training because they were made with the ease of the user in mind. - Versatile Application

Tabletop strapping machines can easily handle boxes, bundles, and other products and are suitable for a variety of packaging sizes and materials. - Adjustable Tension

In order to ensure secure strapping without causing damage to sensitive products, the tensioning mechanism can be modified to accommodate varying package sizes and requirements. - Energy Efficiency

Many contemporary versions have energy-saving features that lower operating expenses, like automated shut-off when not in use.

Advantages of Using Table Top Strapping Machines

- Improved Efficiency

Businesses can package more things in less time thanks to these devices, which drastically cut down on the amount of time needed for manual strapping. - Cost-Effective

Tabletop strapping devices provide a high return on investment by lowering labor expenses and material waste. - Enhanced Package Security

Regular strapping lowers the chance of damage or tampering by ensuring that shipments stay secure during transit. - User-Friendly Operation

Businesses with seasonal workforce or frequent employee turnover can use the machine because operators can learn how to use it quickly. - Mobility

Many tabletop models are portable and light, making it simple to move them around a space for optimal versatility.

Applications of Table Top Strapping Machines

1. Logistics and Warehousing

Securing items is crucial in logistics to guarantee safe transportation. This procedure is made more efficient by tabletop strapping machines, which lower transit risks and increase output.

2. Retail Packaging

These devices are used by retailers to bundle products together, particularly during sales or promotions. They are small and effective, and they blend in perfectly with packaging and backstage spaces.

3. E-Commerce and Fulfillment Centers

Tabletop strapping machines are now essential for making sure that shipments are safely packed and prepared for delivery as e-commerce grows.

4. Food and Beverage Industry

These devices are perfect for safely handling and storing boxes of packaged goods, drinks, or raw materials.

5. Printing and Publishing

Strapping machines are frequently used by publishers and printers to bundle printed items for distribution, such as newspapers, magazines, and books.

Factors to Consider When Choosing a Table Top Strapping Machine

- Strap Compatibility

Verify that the machine can handle the kind and dimensions of straps you intend to use. - Speed and Output

To meet your operational needs, take into account the machine's hourly package handling capacity and strapping speed. - Durability and Build Quality

To guarantee lifespan and dependability, select machinery constructed from premium materials. - Ease of Maintenance

To cut down on downtime and repair expenses, choose models that are simple to clean and maintain. - Energy Efficiency

Energy-efficient models can lower operating expenses, especially for companies that need a lot of strapping.

Innovations in Table Top Strapping Machines

The packaging industry is witnessing continuous innovation, and table top strapping machines are no exception. Recent advancements include:

- Automated Operation

. The use of fully automated models that need little human involvement is growing in popularity. - Eco-Friendly Strapping Options

In line with environmental objectives, machines now accept recyclable or biodegradable strapping materials. - Enhanced Safety Features

Safety features are included into modern equipment to guard against unintentional injuries while they are in use. - Smart Technology Integration

Some versions have IoT-enabled capabilities that enable remote diagnosis and monitoring.

Conclusion

For companies looking to streamline their packing procedures, tabletop strapping devices are revolutionary. They are an essential tool in many industries due to their small size, simplicity of use, and adaptability. Purchasing a tabletop strapping machine guarantees safe, effective, and expert packing whether you run a little business or are a part of a larger enterprise.

These devices not only improve operational efficiency but also help create a more environmentally friendly packaging industry by integrating cutting-edge technologies and sustainable practices. A tabletop strapping machine is definitely a wise investment if you want to optimize your packing process.