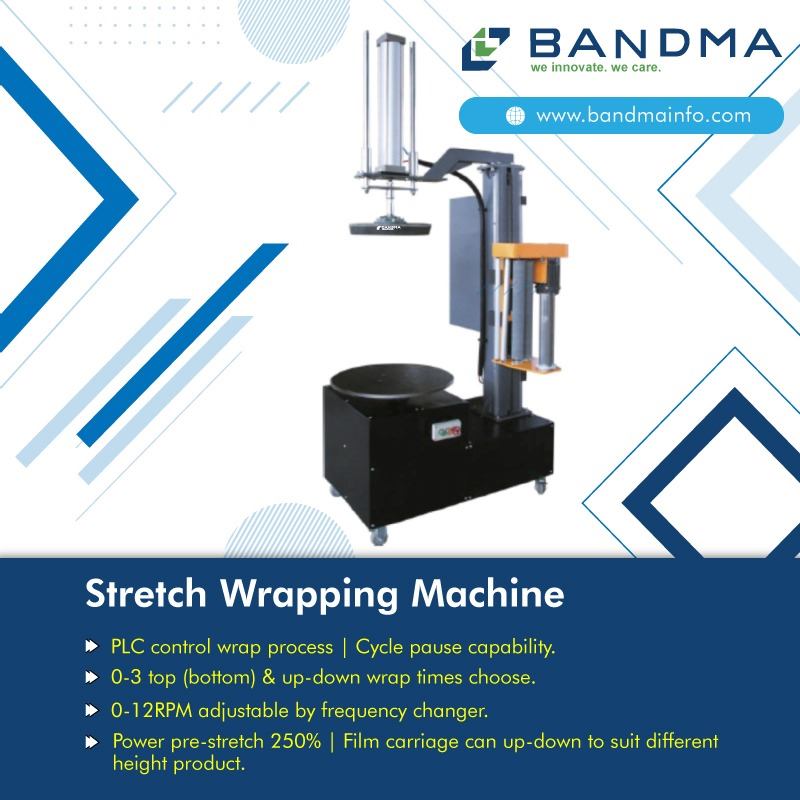

The stretch wrapping machine is manually as well as an electrically powered machine used in companies for large-scale wrapping of the products with stretch film. These machines assist in the reduction of labor as it is mostly automated. In the whole process of attaching, detaching, and pressing the film for the good/product to be wrapped by the machine, the operator only needs to put the product on the table and turn the switch on to operate.

Some of the salient attributes of these machines include stable operations, simple and robust structure, excellent wrapping of products, reduced cost, environmental impact, and consistent film stretch which increase the film stretch rate resulting in low film consumption.

Types of Stretch Wrapping Machines:

Coil Stretch Wrapping Machine

This machine is mainly used for drip coil spiral or Periphery wrapping of coil/donut shaped goods like sheet metal coils, stitching wire coil, vehicle tires, etc.

Some salient features of this wrapping machine include:-

- Controllable film overlap.

- Adjustable cycle time.

- Can be used for wrapping a wide variety of coil sizes in the same machine.

Pallet Wrapping Machine

This machine as the name indicates involves the use of stretch film for wrapping goods. The film is stretched by the machine consistently which results in low file consumption yet perfectly wrapped product/pallet. This same process keeps on repeating till the product/pallet is perfectly wrapped.

Feature of pallet wrapping machine includes:-

- Robust construction

- Controllable cycle time

- Controllable power stretching

- Indigenous design

- Inbuilt safety features

Box Wrapping Machine

The box wrapping machine is used to wrap carton-type goods/products which majorly include pharmaceuticals, cosmetics, consumer goods, engineering items, electrical and electronic components, etc.

Some features of the box wrapping machine include:-

- It is designed for wrapping a wide variety of box sizes in the same machine.

- Controllable film overlapping.

- Auto and manually controllable cycle time.

- It’s easier to operate as compared to other machines.

- It has an optional film power stretching.

The stretch wrapping machines reduce waste, are environment friendly, and increase load stability apart from reducing man labor. By using these machines one can keep their goods safe from damage and spill during transportation and deliveries.

BANDMA - we innovate. we care.

Just send us your questions and we will give you the help you need.