Introduction

In today’s competitive market, packaging is more than just a way to cover products. It plays a vital role in protecting goods, improving presentation, and ensuring smooth logistics. Two popular packaging methods—shrink wrapping and stretch wrapping—often confuse businesses when choosing the best fit. While both are designed to secure products, they work differently and are suitable for different needs. This blog will help you understand the key differences, benefits, and considerations so you can decide which wrapping method is right for your business.

What is Shrink Wrapping?

Shrink wrapping involves covering products with a special plastic film that shrinks tightly when heat is applied. This method creates a tamper-proof, secure, and visually appealing package.

Where it is used:

- Food items (bottles, snacks, baked goods)

- Pharmaceuticals and cosmetics

- Electronics and consumer goods

Key benefits:

- Enhances product presentation with a clean, glossy finish.

- Protects against dust, moisture, and tampering.

- Ideal for single products or small bundles.

What is Stretch Wrapping?

Stretch wrapping, on the other hand, uses stretchable plastic film wrapped tightly around products—usually cartons or palletized goods. Unlike shrink wrapping, no heat is required. The tension of the film keeps the load stable.

Where it is used:

- Large shipments and pallets

- E-commerce logistics and warehouses

- Manufacturing and distribution centers

Key benefits:

- Provides stability during transport.

- Saves cost for bulk shipments.

- Faster process, especially with automatic stretch wrapping machines.

Shrink Wrapping vs. Stretch Wrapping: The Core Differences

Feature | Shrink Wrapping | Stretch Wrapping |

Application | Individual products or small bundles | Large cartons, pallets, and bulk shipments |

Process | Requires heat to shrink film | Uses tension to stretch film |

Appearance | Neat, glossy finish for retail display | Industrial look, not focused on aesthetics |

Protection | Protects from dust, moisture, tampering | Prevents load shifting and damage in transit |

Cost Efficiency | More suitable for retail packaging | More suitable for high-volume logistics |

Which One Should Your Business Choose?

Choose Shrink Wrapping if:

- You want tamper-proof retail-ready packaging.

- Your focus is on presentation and product visibility.

- You deal with smaller packs, food, or cosmetic products.

- You want tamper-proof retail-ready packaging.

Choose Stretch Wrapping if:

- Your goal is to move goods securely in bulk.

- You manage warehouse or logistics operations.

- You want to reduce shipping damages and labor costs.

- Your goal is to move goods securely in bulk.

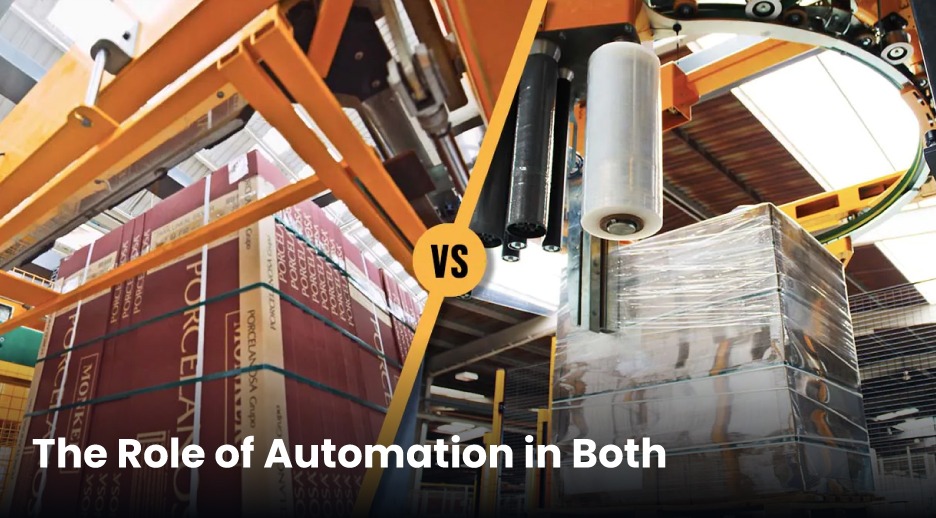

The Role of Automation in Both

Today, businesses are moving towards automated shrink wrapping and stretch wrapping machines. Automation ensures speed, consistency, and reduced errors compared to manual methods. For high-volume industries, these machines directly improve efficiency and ROI.

Conclusion

Both shrink wrapping and stretch wrapping serve important but different purposes. Shrink wrapping is ideal for retail-ready products, while stretch wrapping is best for bulk shipments and secure transportation. The right choice depends on your business needs—presentation vs. protection, small packs vs. large loads.

By evaluating your packaging requirements, you can invest in the right technology that saves costs, reduces product damage, and improves customer satisfaction.