In today's cutthroat industrial, logistics, and e-commerce environments, efficient packaging is become a need rather than a luxury. The packaging process needs to change to keep up with the ongoing pressure on businesses to reduce operating costs, meet deadlines, and meet rising demand.

This combo machine is the secret to quicker, safer, and more reliable packing because it was created with state-of-the-art engineering and constructed to industrial standards. We look at how Bandma's taping and strapping combo system enhances package integrity, boosts productivity, and provides organizations in a variety of industries with tangible operational benefit in this blog.

Why Efficiency Matters in Modern Packaging

Packaging is the last but most crucial step in the production and logistics process. A small delay or inconsistency at this stage can disrupt the entire supply chain. Whether you're preparing goods for shipment, storage, or retail shelves, packaging must be:

- Fast

- Reliable

- Cost-effective

- Consistent

- Secure

Traditionally, taping and strapping have been treated as separate stages—requiring two machines, two operators, and twice the space. Bandma has reimagined this process by integrating both functions into a single combo unit, eliminating inefficiencies and reducing operational burdens.

What Is Bandma’s Taping and Strapping Combo System?

A small, fully automated device that combines high-speed strapping and carton sealing (taping) is Bandma's Box Taping and Strapping Combo System. In a single, smooth motion, the device straps a box for extra protection after automatically applying tape to seal the top and bottom.

Key Features Include:

- A fully automated procedure for strapping and taping

- Adaptable for different box dimensions

- Fast and precise functioning

- A control panel with ease of use

- Sturdy and long-lasting frame for demanding applications

- Human intervention is minimally necessary.

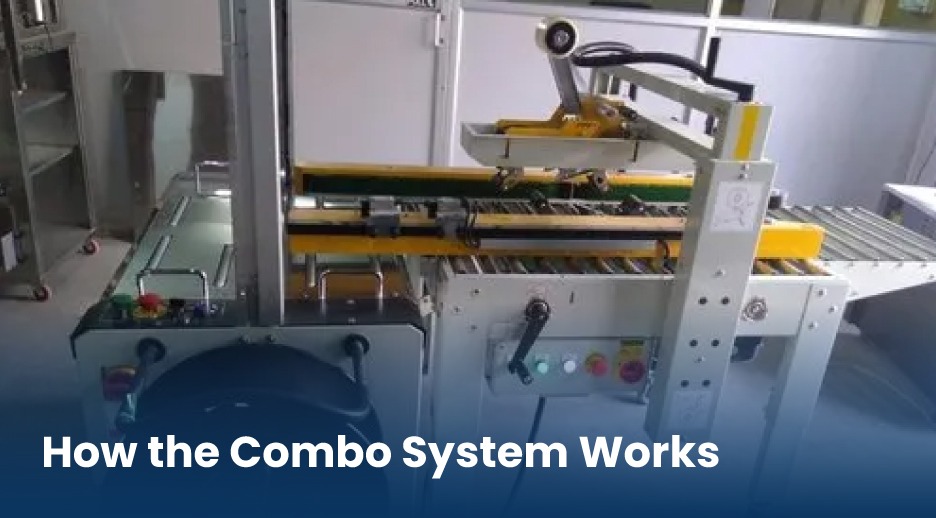

How the Combo System Works

- Box Insertion: The machine either automatically or manually feeds the carton.

- Taping Process: BOPP or kraft tape is applied to the top and bottom flaps by the machine.

- Transfer Section: The strapping unit receives the sealed box straight.

- Strapping Process: The machine uses PP or PET strapping material to apply one or two straps around the box.

- Discharge: The box is prepared for shipping or stacking after it has been completely sealed and secured.

Benefits of Bandma’s Combo System

- Space-Saving Design

When one machine can perform both tasks, why install two different ones? Bandma's combination system's small footprint conserves important floor space, making it the perfect choice for factories, warehouses, and logistics hubs with limited space. - Time Efficiency

Compared to manual or semi-automatic approaches, the combination system's dual automation allows it to process more boxes each hour. Faster order fulfillment is the result, which is particularly crucial for high-volume enterprises. - Labor Cost Reduction

Fewer human resources are required because a single operator may manage both strapping and taping through a single interface. This results in considerable labor cost savings over time. - Consistent Packaging Quality

Loose strapping or inconsistent taping might result in damaged products and unhappy customers. Every time, properly sealed packages are produced thanks to Bandma's combination system, which guarantees accurate tension control and consistent tape application. - Increased Safety

Automation reduces the need for manual strapping and taping equipment, which lowers the possibility of unintentional harm or repetitive strain injuries. - Versatile Application

The combo machine is perfect for a variety of industries, including electronics, pharmaceuticals, FMCG, and automotive components, because it works with a broad range of carton sizes and packaging materials.

Technical Specifications Snapshot

Feature | Specification |

Machine Type | Taping + Strapping Combo |

Taping Material | BOPP, Kraft Tape |

Strapping Material | PP, PET |

Box Size Range | Adjustable (Customizable) |

Speed | High-speed automated cycle |

Power Supply | Standard Industrial Grade |

Operation | User-friendly touch panel |

Note: Bandma offers customization based on customer-specific requirements.

Industries That Benefit from Bandma’s Combo System

Bandma’s Taping and Strapping System is suitable for a variety of sectors, including:

- E-commerce and Retail

Timely deliveries and fewer product returns are guaranteed with quick and safe packaging for large shipments. - Manufacturing

Bottleneck-free assembly line packing is supported by automated strapping and sealing. - Automotive and Spare Parts

To keep heavy-duty boxes with replacement parts from moving while in transit, they require sturdy, reliable strapping. - FMCG and Food Processing

Hygiene and visual uniformity on store shelves are guaranteed by seamless packaging for consumable goods. - Pharmaceuticals

Tamper-proof and precisely sealed packages are essential in pharmaceutical logistics, and Bandma provides both.

Why Choose Bandma?

In the packing machinery sector, Bandma is a well-known Indian brand that is renowned for its inventiveness, dependability, and post-purchase support. With decades of experience, the company has continuously provided SMEs and major enterprises with high-quality, tailored solutions.

Bandma’s Value Proposition:

- Expert engineering and product design

- Durable and easy-to-maintain machinery

- Nationwide customer support

- On-site installation and training

- Customized solutions for diverse packaging needs

Conclusion: One Machine, Unlimited Efficiency

In today's cutthroat business environment, automated packaging solutions are now necessary rather than optional. Bandma's Box Taping and Strapping Combo System is a clever, portable, and economical method to expedite your packing processes without sacrificing speed or quality.

Regardless of the volume of boxes you process each day—500 or 5,000—this machine is built to grow with your company and provide unparalleled dependability and efficiency.