In today’s world, sustainability is no longer an option—it’s a responsibility. Businesses across industries are under growing pressure to reduce their environmental impact and adopt greener practices. One significant step in that direction is minimizing carbon emissions throughout the supply chain. And while many organizations focus on raw materials or transportation, packaging plays an equally critical role.

Manual packaging processes, although familiar, often involve inefficiencies that lead to waste—extra film, excessive energy consumption, and inconsistent packaging quality. This is where packaging automation steps in, helping companies not only save time and costs but also reduce their carbon footprint in measurable ways.

Let’s explore how automated packaging systems can transform sustainability goals into reality.

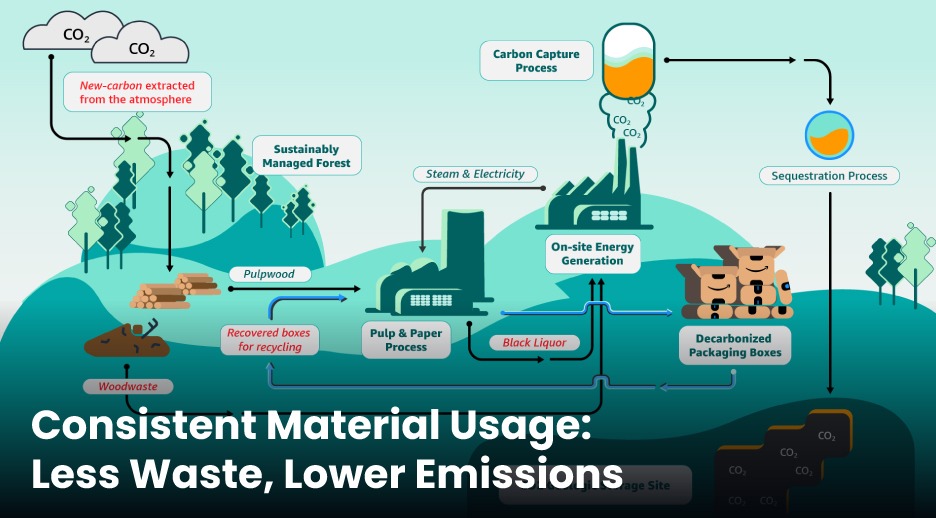

1. Consistent Material Usage: Less Waste, Lower Emissions

When packaging is done manually, there’s always the risk of overuse or underuse of materials. For example, workers may wrap extra layers of stretch film “just to be safe,” leading to unnecessary plastic waste. Over time, this adds up—not only increasing material costs but also contributing to higher carbon emissions associated with producing and disposing of that excess plastic.

Automated packaging machines eliminate this problem. These machines apply precisely the right amount of material, ensuring every package is secured without waste. By reducing film consumption by up to 30–50%, businesses can significantly cut down the energy and resources required to manufacture and transport packaging materials—directly reducing their carbon footprint.

2. Energy Efficiency: Doing More with Less

Modern packaging equipment is designed with energy efficiency in mind. Unlike older machinery or manual systems that require continuous human effort and lighting for extended hours, automated machines operate on optimized energy settings. Features like auto-sleep modes, low-energy motors, and smart sensors ensure that the machine only consumes power when needed.

This means businesses can process higher volumes of packages using less energy per unit, reducing overall greenhouse gas emissions tied to electricity usage. When combined with renewable energy sources, the environmental impact becomes even smaller.

3. Fewer Errors = Fewer Returns

One often-overlooked factor in a company’s carbon footprint is product returns. Poorly packed goods are more likely to get damaged during transit, leading to returns and replacements. Every returned shipment means additional transportation, more packaging materials, and increased energy use—all of which add to carbon emissions.

Automation minimizes this risk by ensuring consistent, secure, and reliable packaging every time. With fewer errors and damages, businesses can reduce reverse logistics and the environmental burden that comes with it.

4. Optimized Film Technology with Pre-Stretch Systems

Advanced stretch wrapping machines come with pre-stretch technology, which stretches the film before it is applied to the load. This allows a single roll of film to cover more pallets compared to traditional wrapping. The result? Lower material consumption, fewer roll changes, and reduced manufacturing emissions for film production.

Pre-stretch systems can achieve film savings of up to 250–300%, which is a game-changer for businesses that process high shipping volumes. Not only does this reduce costs, but it also directly supports environmental sustainability goals.

5. Reduced Transportation Emissions through Load Stability

Poorly wrapped pallets take up more space, shift during transit, or require additional reinforcement, which leads to inefficiencies in truck loading. Automation ensures tight, stable, and space-efficient loads, allowing businesses to maximize the number of products per truckload.

Fewer trips mean lower fuel consumption and reduced carbon emissions in transportation. When combined with optimized route planning, the environmental savings are substantial.

6. Smart Integration with Sustainability Initiatives

Many automated systems today are designed to integrate with data analytics and IoT platforms. This allows companies to track material usage, energy consumption, and efficiency levels in real-time. Having this data enables businesses to set sustainability targets, monitor progress, and identify further areas for improvement.

For example, if a company notices that a particular line is consuming more energy or film than expected, adjustments can be made immediately. This proactive approach ensures a continuous reduction in the carbon footprint.

7. Improved Worker Safety and Efficiency

Although this doesn’t directly reduce carbon emissions, it contributes to overall sustainability by improving operational efficiency. Automation reduces the need for workers to manually lift, wrap, or move heavy loads—leading to fewer injuries, less downtime, and more consistent output. A smooth workflow translates to less wasted energy, materials, and time—all of which support greener operations.

The Big Picture: Sustainability Beyond Cost Savings

For many businesses, the first motivation to adopt packaging automation is cost efficiency. But the environmental benefits are just as important—if not more. By reducing material waste, lowering energy consumption, minimizing transportation inefficiencies, and cutting down on returns, automated packaging plays a vital role in building a low-carbon supply chain.

Sustainability is no longer a marketing buzzword; it’s a competitive advantage. Customers today actively seek out brands that demonstrate environmental responsibility. Governments and global organizations are introducing stricter carbon regulations. By investing in packaging automation, businesses position themselves as forward-thinking, eco-conscious leaders in their industry.

Conclusion

Cutting down the carbon footprint in packaging doesn’t happen overnight, but automation is a major step in the right direction. It’s not just about speeding up operations—it’s about doing more with less, eliminating waste, and aligning with the global push toward sustainability.

So, if your business is serious about reducing its environmental impact, it’s time to look beyond manual processes and embrace smart packaging automation. It’s an investment that benefits your bottom line—and the planet.