In the world of industrial packaging, precision, speed, and reliability are no longer luxuries they are absolute necessities. As global trade expands and supply chains become more complex, manufacturers are under constant pressure to deliver consistent quality, reduce costs, and maintain operational efficiency.

That’s where Bandma’s strapping technology comes in transforming traditional packaging methods into intelligent, high-performance systems that set new benchmarks for industrial excellence.

For more than three decades, Bandma has been a leader in India’s packaging automation industry, continually innovating to meet evolving industrial needs. Today, its advanced strapping machines represent a perfect blend of engineering precision, smart technology, and sustainable design redefining how businesses secure, handle, and ship their products.

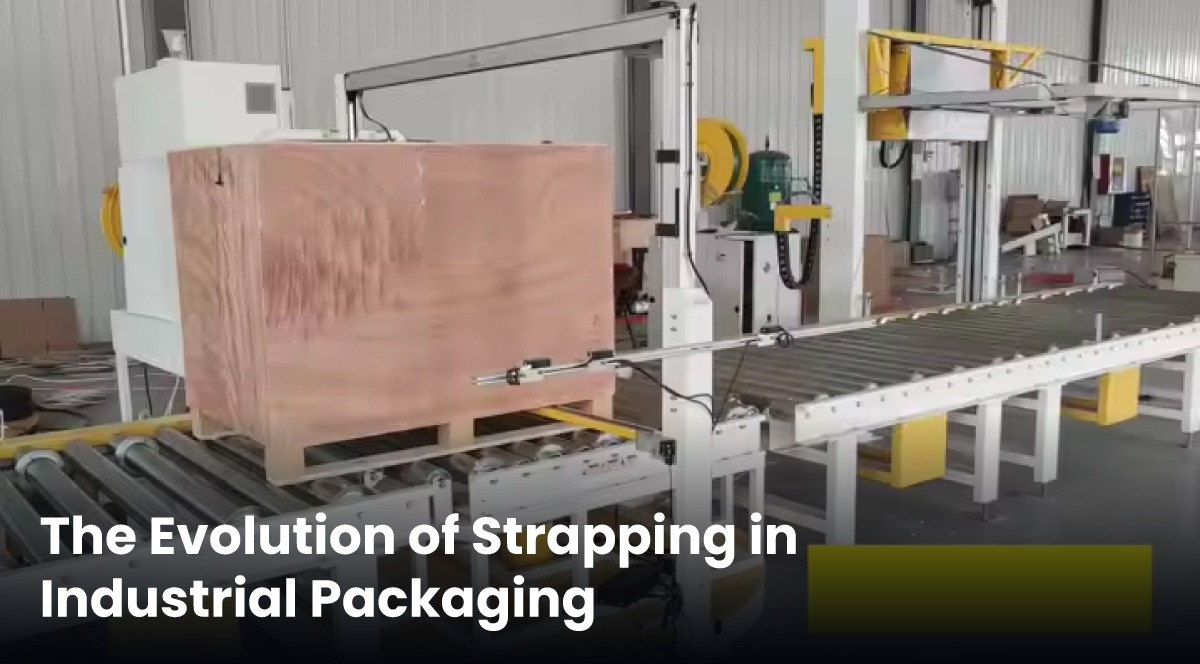

1. The Evolution of Strapping in Industrial Packaging

Strapping the process of securing bundles, boxes, or pallets with a plastic or steel strap has always played a critical role in packaging. Traditionally, this was a labor-intensive and time-consuming process, prone to inconsistencies and inefficiencies.

Bandma revolutionized this segment by introducing automated strapping machines that perform the task with unmatched accuracy and speed. From semi-automatic models ideal for SMEs to fully automatic and high-speed strapping systems designed for heavy-duty industrial applications, Bandma’s solutions cater to every production scale.

These machines are not just tools; they’re intelligent systems that optimize performance, reduce manual effort, and maintain consistent packaging quality across every product batch.

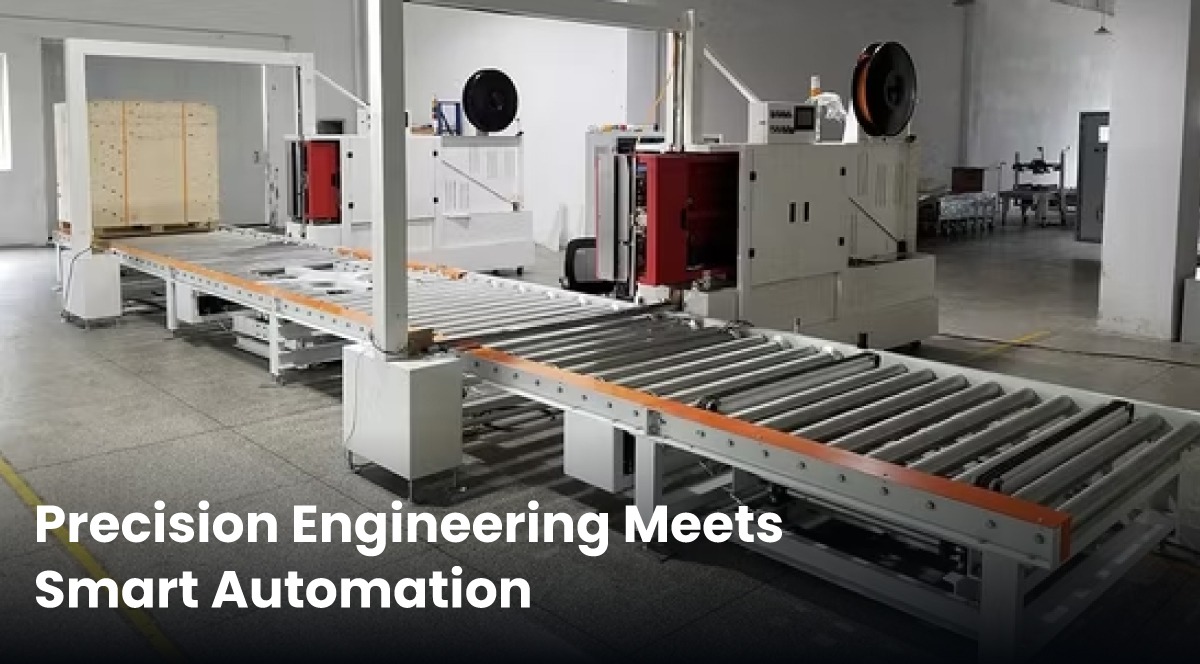

2. Precision Engineering Meets Smart Automation

At the heart of Bandma’s strapping technology lies precision engineering backed by automation. Each machine is built with PLC (Programmable Logic Controller) technology, photo sensors, and microprocessor-based controls, ensuring flawless operation and consistent tension levels.

Bandma’s automatic strapping machines detect packages, feed and tension the strap, seal it with heat or friction, and cut the excess all within seconds. The result? Perfect, uniform strapping every single time.

This automation not only eliminates human error but also enhances production speed enabling businesses to meet tight delivery timelines without compromising on packaging quality.

3. Durability and Performance You Can Trust

Industrial environments demand machines that can withstand continuous operation under challenging conditions. Bandma’s strapping machines are built from high-grade components and corrosion-resistant materials, ensuring long service life with minimal maintenance.

Each model undergoes rigorous testing for performance, reliability, and energy efficiency before it reaches the customer.

This focus on durability makes Bandma machines a long-term investment for businesses that value consistent uptime and low operational costs.

4. Redefining Speed, Safety, and Sustainability

Bandma’s strapping technology is designed with three key goals: speed, safety, and sustainability.

Speed:

High-performance motors and intelligent tension controls allow machines to complete multiple cycles per minute significantly boosting productivity.

Safety:

Built-in sensors prevent jams, overheating, and strap misfeeds, ensuring operator safety and smoother workflows.

Sustainability:

Bandma promotes eco-friendly packaging by optimizing strap usage, minimizing material waste, and supporting recyclable strapping materials like PP and PET.

By balancing these three factors, Bandma ensures that businesses achieve peak efficiency while reducing their environmental footprint a key expectation in 2025’s global manufacturing landscape.

5. Versatile Solutions for Every Industry

From FMCG and pharmaceuticals to logistics, automotive, and e-commerce, Bandma’s strapping technology has proven its adaptability across diverse industrial sectors.

- Food & Beverages: Securing cartons, crates, and bottled goods with precision.

- Logistics & Warehousing: Strengthening shipments and pallets for long-distance transport.

- Manufacturing Units: Bundling heavy materials, spare parts, and components with industrial-grade strength.

- E-commerce & Retail: Speeding up packaging lines with compact, efficient strapping systems.

Each machine can be customized for product size, strap width, and operation mode — giving businesses complete control over their packaging line.

6. Technology That Thinks Ahead

Bandma’s R&D team continuously pushes the limits of packaging innovation. The company is integrating IoT (Internet of Things) and AI-based monitoring systems into its next generation of strapping machines.

These smart systems allow real-time tracking of machine performance, predictive maintenance alerts, and data-driven optimization.

With such advancements, Bandma is setting the stage for Industry 4.0-ready packaging solutions where machines don’t just operate, they communicate and optimize themselves.

7. Empowering SMEs and Large Industries Alike

One of Bandma’s greatest strengths is its ability to design machines that empower both small businesses and large manufacturers.

For SMEs, Bandma’s semi-automatic strapping machines provide an affordable entry into automation helping them boost productivity and match big players in efficiency.

For large-scale operations, fully automatic strapping lines deliver seamless integration, continuous operation, and unmatched throughput.

This flexibility ensures that every business, regardless of size, can adopt packaging automation at its own pace.

8. The Bandma Commitment: Innovation, Service, and Reliability

Bandma’s reputation isn’t just built on technology it’s built on trust. The brand’s nationwide service network, readily available spare parts, and dedicated customer support make it a reliable partner for thousands of businesses.

Every Bandma machine reflects the company’s commitment to “Make in India” manufacturing excellence combining local innovation with global standards.

By consistently upgrading its technology and listening to customer needs, Bandma continues to lead the Indian packaging industry into a smarter, more sustainable future.

Conclusion

Industrial packaging is evolving and Bandma is driving that evolution. With advanced automation, intelligent engineering, and a strong focus on sustainability, Bandma’s strapping technology is setting new benchmarks for efficiency, reliability, and performance.

Whether you’re a growing SME or a global manufacturer, Bandma gives you the power to package smarter, faster, and stronger redefining what industrial packaging stands for in 2025 and beyond.