In today’s fast-paced supply chain, warehouses are under constant pressure to move goods faster, safer, and at a lower cost. Manual packaging methods often fall short when businesses scale up, leading to delays, inconsistent wrapping, and higher labor expenses. This is where automatic stretch wrapping machines come in, transforming packaging operations into a streamlined, efficient process that saves both time and money.

What Is an Automatic Stretch Wrapping Machine?

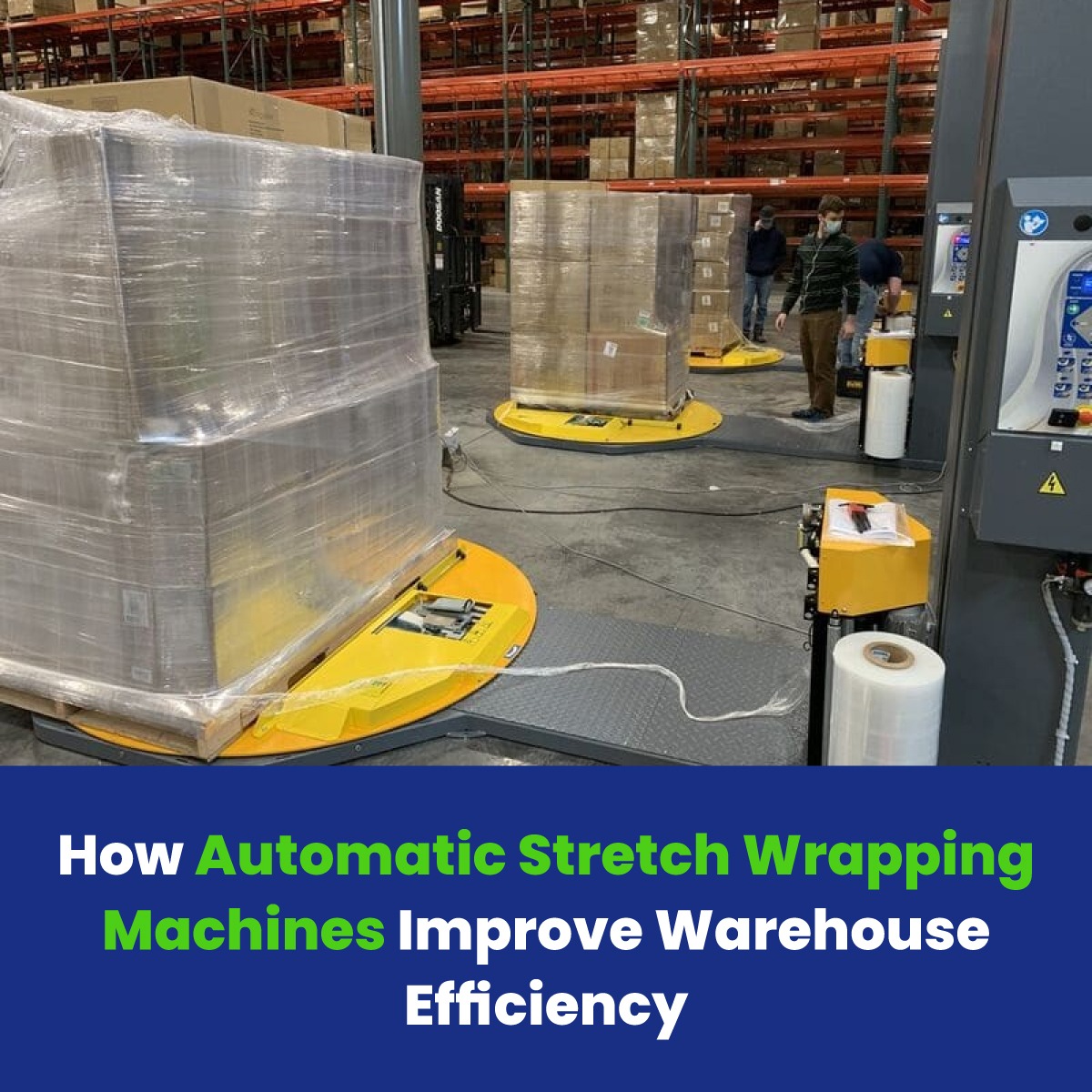

An automatic stretch wrapping machine is designed to wrap palletized goods with stretch film, securing them tightly for storage or transportation. Unlike manual wrapping, which depends heavily on labor and can lead to uneven results, automatic machines use precise controls and advanced mechanisms to ensure every pallet is wrapped uniformly.

By automating this repetitive but crucial task, warehouses can focus labor resources on other areas of operation while achieving higher levels of consistency and efficiency.

Key Benefits of Automatic Stretch Wrapping Machines

1. Faster Operations

Time is money in warehousing. Manual wrapping requires multiple workers and significant effort, but an automatic machine can wrap a pallet in just a fraction of that time. This speed allows warehouses to process more shipments daily, directly boosting throughput.

2. Consistent Wrapping Quality

Inconsistent wrapping can lead to loose loads, product damage, and increased returns. Automatic stretch wrappers apply the film with uniform tension and coverage, ensuring pallets are stable and secure every single time. Consistency also reduces customer complaints and improves trust in your deliveries.

3. Reduced Stretch Film Wastage

Film wastage is a hidden cost many warehouses overlook. When done manually, operators often use too much film to ensure load security, leading to unnecessary expenses. Automatic machines are engineered to stretch film optimally, reducing material use without compromising strength. This can significantly lower packaging costs over time.

4. Improved Load Stability and Safety

Load stability is essential for preventing accidents and protecting goods during transportation. Automatic stretch wrappers provide tighter, more secure wraps, minimizing the risk of products shifting, toppling, or getting damaged. Enhanced stability also improves workplace safety, as improperly wrapped pallets are a common cause of accidents.

5. Lower Labor Costs

Manual wrapping is labor-intensive and physically demanding, often leading to worker fatigue and higher turnover rates. By automating the wrapping process, warehouses can reduce dependency on manual labor for repetitive tasks. Workers can then be reassigned to more value-driven activities, increasing overall productivity.

Long-Term ROI: Beyond Immediate Savings

While the initial investment in an automatic stretch wrapping machine may seem high, the long-term benefits far outweigh the cost. Businesses save on film usage, labor expenses, and potential product damage, which directly impacts profitability.

Additionally, reduced downtime and improved efficiency mean warehouses can handle larger volumes without proportionally increasing costs, making the machine a smart investment for long-term growth.

Manual Wrapping vs. Automatic Wrapping: Why Automation Wins

Factor | Manual Wrapping | Automatic Stretch Wrapping Machine |

Speed | Slow, labor-intensive | Fast, consistent, automated |

Film Usage | High wastage | Optimized usage, cost-efficient |

Consistency | Varies by worker | Uniform every time |

Load Stability | Unreliable for heavy loads | Secure and safe |

Labor Requirement | Multiple workers | Minimal supervision |

The comparison makes it clear: automation is not just about convenience, but about creating a stronger, more sustainable packaging process.

The Future of Warehousing with Automation

As e-commerce and global trade continue to expand, warehouses are embracing automation to stay competitive. Automatic stretch wrapping machines are an essential part of this transformation, enabling businesses to achieve efficiency, safety, and cost-effectiveness at scale.

When combined with other automated solutions, such as carton sealers, strapping machines, and conveyor systems, warehouses can build an end-to-end automated packaging line that delivers unmatched performance.

Conclusion

In the world of warehousing and logistics, efficiency is everything. Automatic stretch wrapping machines play a crucial role in improving speed, consistency, safety, and cost savings, helping businesses meet the growing demands of modern supply chains.

For companies aiming to reduce waste, cut costs, and improve operational flow, investing in an automatic stretch wrapping machine is not just an upgrade; it’s a necessity for long-term success.