The industrial packaging world is transforming faster than ever before. In 2025, Artificial Intelligence (AI) and the Internet of Things (IoT) are no longer futuristic buzzwords they’re real, impactful technologies driving how packaging machines think, learn, and optimize operations. From predictive maintenance to sustainability, AI and IoT are changing how manufacturers pack products and run production lines.

Let’s dive into how these innovations are reshaping the future of packaging.

1. From Automation to Intelligence

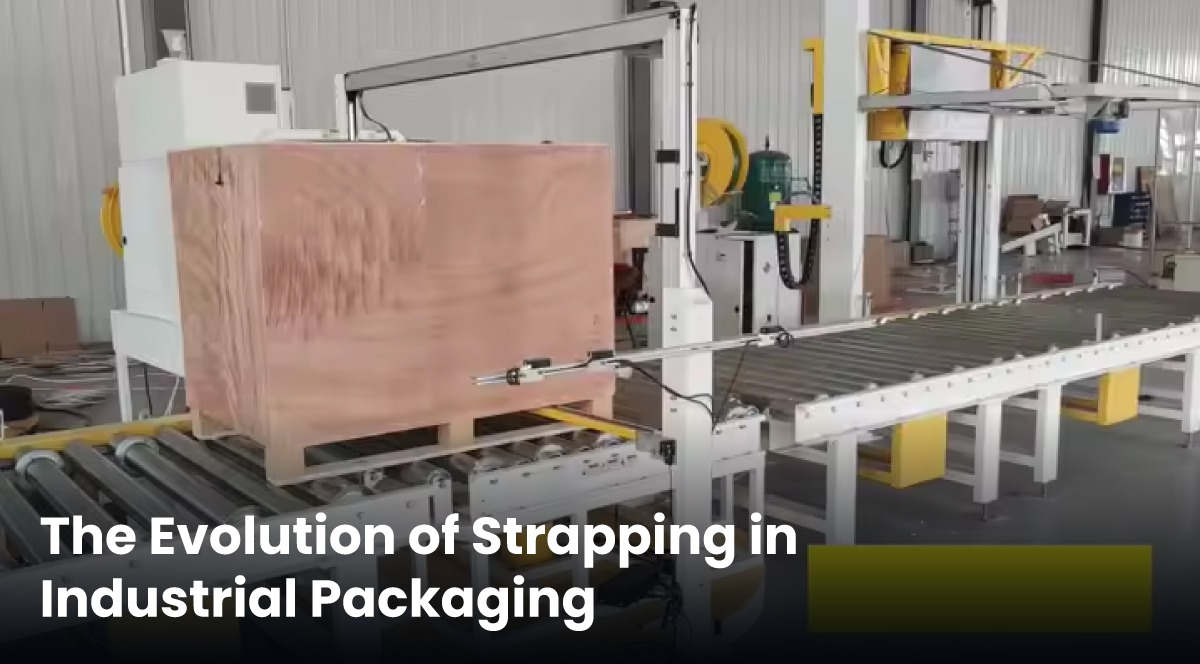

Traditional packaging systems were designed to automate repetitive tasks sealing boxes, wrapping pallets, or labeling products. But AI and IoT have taken automation to the next level.

IoT sensors embedded in machines now track temperature, vibration, pressure, and energy usage in real time. AI algorithms analyze this data to identify inefficiencies and automatically adjust settings for better performance.

For example, an intelligent wrapping machine can adapt its tension or speed based on the product’s shape and weight. This reduces waste, improves consistency, and cuts manual effort. In short, machines have become smarter, not just faster.

2. Predictive Maintenance: Avoiding Downtime

One of the biggest challenges in manufacturing is unexpected machine breakdowns. In the past, equipment was repaired after failure leading to costly delays. Today, AI and IoT enable predictive maintenance, turning reactive systems into proactive ones.

IoT sensors continuously monitor the health of machines tracking vibration, temperature, and motor performance. AI models use this data to predict when a part might fail and alert operators in advance.

This approach not only prevents sudden breakdowns but also reduces repair costs and extends equipment life. Studies show predictive maintenance can reduce downtime by up to 40% a huge gain for high-volume packaging plants.

3. Smarter Quality Control

Packaging quality defines brand perception. Even small defects like a loose seal or a misprinted label can lead to returns or product recalls. AI-powered vision systems are now taking quality control to the next level.

Using high-speed cameras and machine learning, these systems inspect thousands of packages per hour. They instantly detect issues like damaged packaging, misaligned labels, or incorrect barcodes.

What makes them powerful is their ability to learn. Each inspection improves the AI’s accuracy, creating a self-improving quality control loop. The result: higher consistency, less waste, and better customer satisfaction.

4. Robotics and Cobots in Action

In 2025, robotic automation is everywhere in packaging. Smart robots and cobots (collaborative robots) are handling repetitive, high-speed, and heavy tasks like stacking cartons, sealing boxes, or applying labels.

With AI integration, these robots can adapt to changing product sizes or packaging materials automatically. Cobots are also designed to work safely alongside humans making production lines more flexible and efficient.

As labor shortages continue in manufacturing, robotics powered by AI and IoT are proving essential for maintaining productivity and reducing human strain.

5. Sustainability Through Smart Packaging

Sustainability is no longer just a marketing buzzword it’s a business priority. AI and IoT technologies help manufacturers make packaging greener and more efficient.

IoT sensors monitor energy consumption and material usage in real time. AI systems analyze this data and recommend ways to cut waste for instance, optimizing wrapping film thickness or reducing idle machine time.

By precisely controlling resources, companies can minimize material waste, lower electricity costs, and reduce their carbon footprint. This balance of performance and sustainability gives manufacturers a strong competitive edge.

6. Real-Time Data and Connected Operations

IoT has turned packaging plants into fully connected ecosystems. Every machine, sensor, and operator is linked through a central network. Managers can now view live data machine performance, energy use, or output rates from a single dashboard.

AI transforms this data into actionable insights. If production slows, the system identifies the issue and suggests fixes instantly. This level of visibility enhances productivity, reduces errors, and allows teams to make quick, data-driven decisions.

Additionally, real-time data helps align packaging with supply chain operations. Packaging output data can be shared with logistics teams to streamline inventory and shipment planning making the entire process faster and more transparent.

7. Challenges and the Road Ahead

While AI and IoT offer huge advantages, they also bring challenges. Data security is one since connected machines generate large amounts of sensitive information, protecting it from cyber threats is essential.

Integration with older, legacy systems can also be tricky. Many manufacturers still use traditional machines that lack connectivity. However, new plug-and-play IoT modules and smart retrofitting solutions are making it easier to modernize existing setups.

Looking ahead, the rise of edge computing (local data processing) will make IoT systems even faster, and AI will evolve to manage entire packaging lines autonomously. The industry is moving toward machines that don’t just do tasks they decide how to do them better.

Conclusion

AI and IoT have turned industrial packaging into a smart, connected ecosystem. From predictive maintenance and robotics to quality assurance and sustainability, these technologies are redefining how packaging works.

In 2025, the most successful packaging companies are those that embrace intelligence, not just automation. By investing in smart machines and data-driven systems, manufacturers can boost efficiency, reduce waste, and stay future-ready.

The future of packaging is here and it’s powered by AI and IoT.