In the fast-paced world of industrial packaging today, it is imperative to protect the quality and freshness of goods, particularly perishables. Manufacturers of everything from electronics and fast-moving consumer goods to food and medications are looking for clever packaging solutions that can not only properly seal but also protect the contents. By integrating speed, accuracy, and product longevity into a single, small system, Bandma's Nitrogen Flushing Band Sealer performs very well in meeting this goal.

Why Nitrogen Flushing Matters

The function of nitrogen flushing in packaging must be understood before delving into Bandma's band sealer's characteristics. Prior to sealing, nitrogen gas is introduced into the package as part of the nitrogen flushing process. Moisture and oxygen, which cause rust, mold, spoiling, and staleness, are displaced in this way.

Nitrogen flushing is beneficial when working with food items, delicate medications, or fragile electrical components.

- Extend Shelf Life

- Prevent Oxidation

- Maintain Texture and Flavor

- Protect Against Moisture and Contamination

This makes nitrogen flushing a crucial step in modern packaging where product freshness directly impacts consumer satisfaction and brand reputation.

Introducing Bandma’s Nitrogen Flushing Band Sealer

At Bandma, we recognize how important it is to have dependable, high-performing sealing equipment. With the least amount of manual labor, our nitrogen flushing band sealer offers speed and accuracy for medium-to high-volume packing operations.

Key Features at a Glance:

- Nitrogen Flushing System

Integrated nitrogen injection guarantees that food-grade nitrogen gas is flushed into your products before to sealing. This functionality is particularly helpful for food packing, including snacks, coffee, tea, spices, and baked goods. - High-Speed Continuous Sealing

Bandma's sealer can process hundreds of pouches per hour and has a sturdy conveyor with continuous sealing capabilities, making it ideal for sectors with high demand. - Adjustable Temperature & Speed Controls

Consistent results across batches are ensured by operators' easy adjustment of conveyor speed and sealing temperature based on material thickness and type. - Heavy-Duty Construction

The sealer is made to last in tough manufacturing situations using materials of the highest quality. - User-Friendly Operation

With little training, workers can easily operate the machine thanks to its straightforward interface and user-friendly control panel. - Compact Design

It may be integrated into smaller packing units or current production lines due to its space-saving design.

Why Nitrogen Flushing is a Game Changer

These days, packaging includes preservation and display in addition to wrapping and sealing. Nitrogen flushing is now a necessary procedure in the packing of:

- Food Products (snacks, cereals, coffee, dairy, spices)

- Pharmaceuticals (tablets, powder sachets, herbal products)

- Electronics & Components (moisture-sensitive items)

- Cosmetics & Chemicals (creams, lotions, chemical powders)

In addition to extending shelf life, nitrogen maintains flavor, texture, aroma, and nutritional value by eliminating oxygen, making it the most hygienic and expert method of delivering high-quality products.

Industries Benefiting from Bandma's NFBS Technology

Bandma’s Nitrogen Flushing Band Sealer is trusted by various industries for its reliability and versatility:

Industry | Use Case Example |

Food & Beverage | Sealing of chips, dry fruits, spices |

Pharmaceuticals | Packing medicines and supplements |

Agriculture | Packing seeds and fertilizers |

Chemical Industry | Sealing moisture-sensitive powders |

FMCG | High-speed packaging of retail goods |

From small-scale producers to large manufacturing units, Bandma provides scalable sealing solutions that meet international standards.

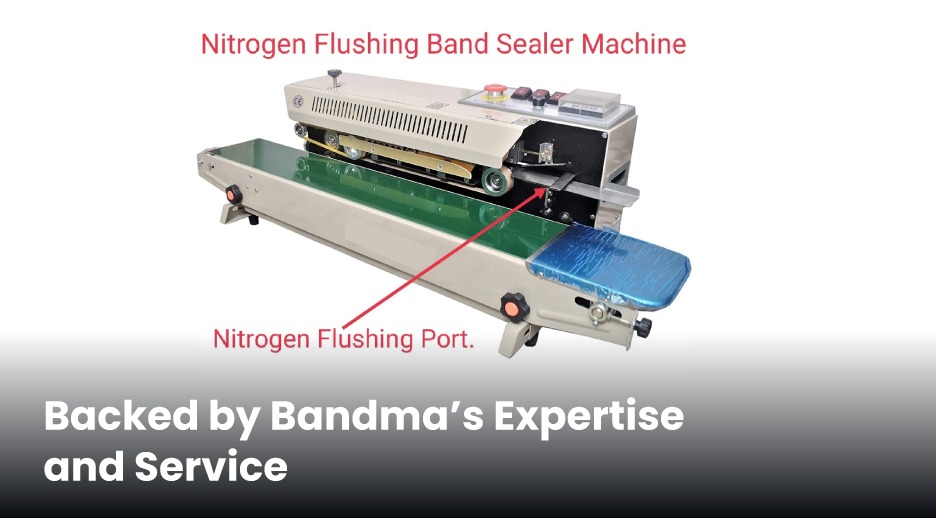

Backed by Bandma’s Expertise and Service

Bandma is a packaging solutions partner in addition to being a supplier of machinery. With more than ten years of experience creating high-performance packing machinery, Bandma is still at the forefront of innovation.

When you choose our Nitrogen Flushing Band Sealer, you gain access to:

- Expert Technical Support

- Custom Machine Configurations

- Flexible Upgrades

- Local and Global Delivery

- After-Sales Service Excellence

We take pride in making sure that our equipment helps you achieve your packaging objectives while lowering waste and raising consumer satisfaction.

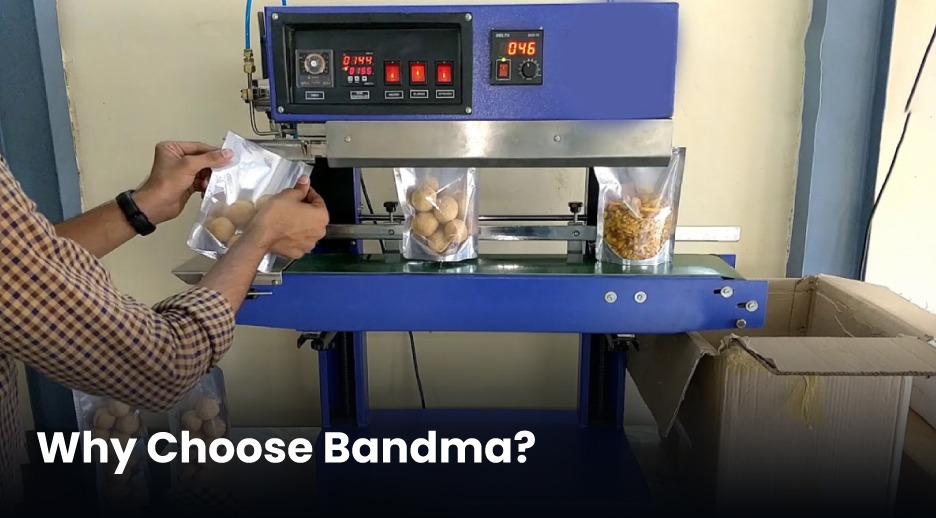

Why Choose Bandma?

Bandma is a respected company in the packaging machines industry that is well-known for offering innovative, superior solutions that boost output and simplify procedures. Our machines are proudly made in India and are built to meet international performance and reliability standards.

When you choose Bandma, you’re not just investing in a machine—you’re gaining a long-term partner committed to your growth.

What Sets Us Apart:

- Customizable Solutions based on specific industry requirements

- In-house R&D to stay ahead with new innovations

- Dedicated After-Sales Support and training services

- Sustainable Packaging Practices to reduce environmental impact

Conclusion: A Seal of Trust and Freshness

The correct sealing solution is crucial in sectors where quality cannot be sacrificed. Your items will always be kept at their best freshness and sealed tightly thanks to Bandma's Nitrogen Flushing Band Sealer. It is a useful addition to any packaging line because of its sophisticated design and high-speed operation.

Now is the perfect time to use Bandma to improve your packaging if you want to increase productivity, decrease spoiling, and increase product shelf life.

Experience the power of precision packaging. Contact Bandma today for a demo or consultation!