Gantry cranes are unique pieces of equipment with unparalleled flexibility, efficiency, and lifting strength in the fast-paced world of industrial operations. Gaining insight into the capabilities and advantages of gantry cranes can revolutionize your operational workflow, regardless of whether you oversee a busy port, an expansive manufacturing facility, or a construction site. We'll go over the many kinds of gantry cranes, their uses, advantages, and crucial upkeep procedures in this blog so you may get the most out of these strong vehicles.

What is a Gantry Crane?

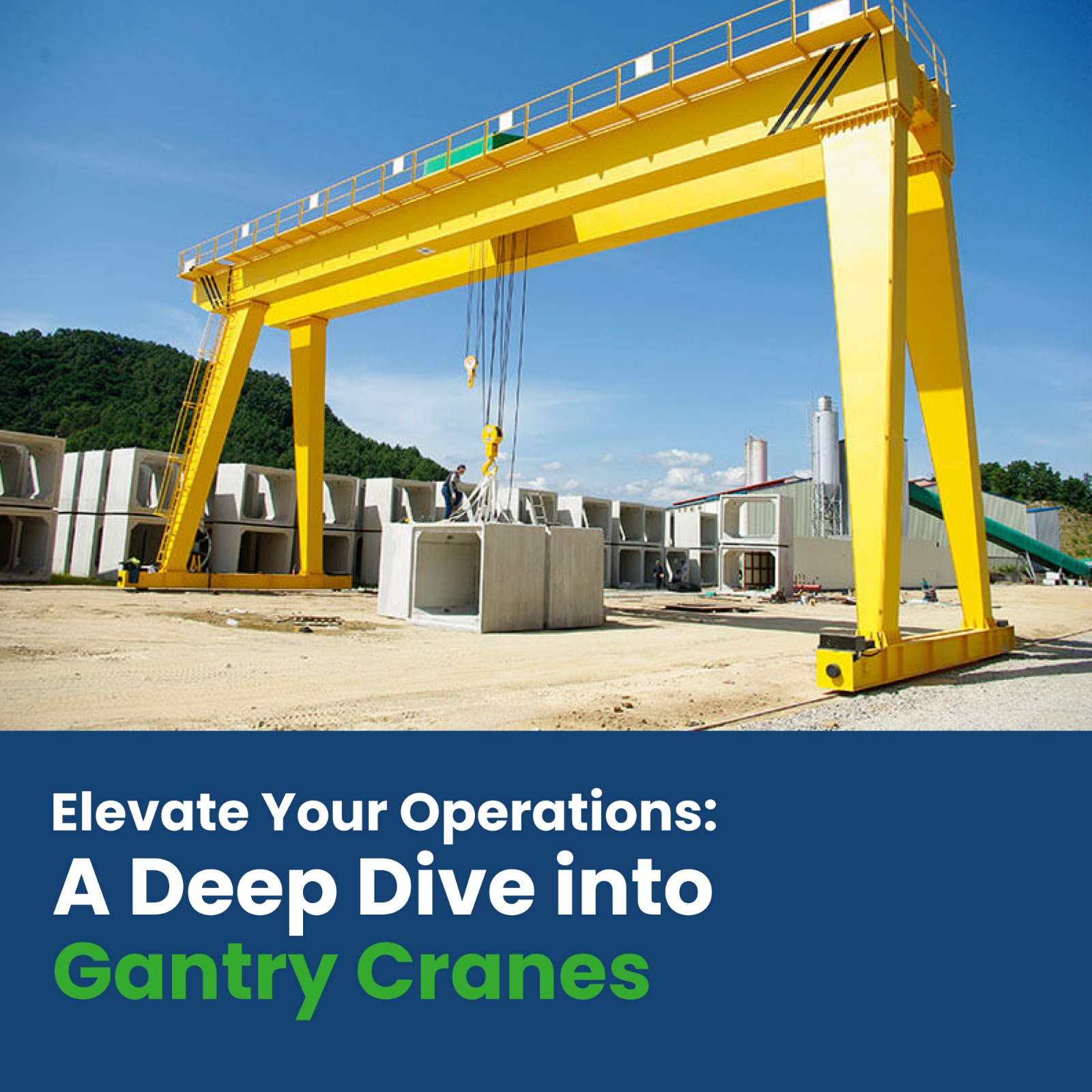

An overhead crane with a bridge supported by freestanding legs that may move on wheels or a track is known as a gantry crane. Gantry cranes are self-supporting, in contrast to conventional overhead cranes, which depend on the building structure for support. Because of their architecture, they are perfect for situations where a permanent crane structure is impractical, both indoors and outdoors.

Types of Gantry Cranes

Gantry cranes come in several configurations, each suited to specific needs:

1. Full Gantry Crane

A complete gantry crane travels on tracks set into the floor, spanning the breadth of a work area. This kind is typical in railyards, shipyards, and sizable manufacturing facilities where heavy lifting is done frequently.

2. Semi-Gantry Crane

Semi-gantry cranes consist of one leg that is fixed to a wall or building column and the other leg that runs on a railing on the ground. This arrangement works well in spaces with little floor room.

3. Portable Gantry Crane

Gantry cranes that are portable are lightweight and simple to put together, take apart, and relocate. For lower loads and facility maintenance duties, they are ideal.

Applications of Gantry Cranes

Gantry cranes are adaptable and have several uses in a range of sectors, including:

1. Shipping and Logistics

Gantry cranes are essential for the safe and effective loading and unloading of shipping containers in ports and container yards.

2. Manufacturing

Gantry cranes are used in manufacturing facilities to move large equipment, components, and supplies, which expedites workflow and streamlines production processes.

3. Construction

Gantry cranes are utilized on building sites to lift and move equipment, prefabricated parts, and building materials, which helps to streamline project completion.

4. Warehousing

Gantry cranes improve storage and retrieval efficiency in warehouses by helping to move big, heavy merchandise.

5. Maintenance and Repair

Gantry cranes that are portable and movable are perfect for maintenance and repair jobs since they offer versatility and user-friendliness in a range of environments.

Benefits of Gantry Cranes

Gantry cranes are a versatile and efficient solution for material handling in various industries. Here are some key benefits of using gantry cranes:

- Versatility and Flexibility:

Warehouses, shipyards, and building sites are just a few of the settings where gantry cranes might be employed. With their height and span adjustments, they can manage a variety of loads and duties. - Cost-Effective:

Gantry cranes are less expensive and require less infrastructure investment than permanent overhead cranes. They save money on installs and renovations since they are easily moved or modified to meet various work environments. - Enhanced Mobility:

A lot of gantry cranes have wheels or tracks, which allow them to carry loads between different areas of a building. This mobility lowers the requirement for extra lifting equipment while improving workflow efficiency. - Increased Load Capacity:

Because gantry cranes can support huge loads, they are perfect for lifting and moving big, bulky objects. Their strong lifting capacities guarantee the secure and effective handling of bulky objects. - Improved Safety:

Modern safety measures including limit switches, emergency stop buttons, and overload protection are installed on gantry cranes. These characteristics support the safety of operators and other staff members by preventing mishaps. - Ease of Installation and Maintenance:

Gantry cranes need little upkeep and are comparatively simple to install. Their ability to be quickly assembled and disassembled thanks to their modular design minimizes downtime and guarantees continuous operation. - Space Efficiency:

Gantry cranes are a great option for facilities with limited space because they don't need a fixed structure or specific floor area. They maximize the amount of workspace that is available in locations where overhead cranes are impractical. - Customization Options:

Gantry cranes can be tailored to fulfill certain operational needs. With a variety of configurations available, including single or double girder, height adjustment, and specialty attachments, enterprises can customize the crane to meet their specific requirements.

Essential Maintenance Tips for Gantry Cranes

To guarantee gantry crane lifetime and peak performance, regular maintenance is essential. Here are some vital upkeep pointers:

1. Regular Inspections

Check for wear and tear, structural integrity, and proper operation of all components by conducting routine inspections.

2. Lubrication

Ensure that all moving parts, such as wheels, bearings, and hoists, are adequately lubricated to reduce friction and prevent wear.

3. Load Testing

Perform regular load testing to verify the crane's lifting capacity and ensure it can handle the specified loads safely.

4. Electrical Systems

Inspect and maintain electrical systems, including wiring, control panels, and limit switches, to prevent malfunctions and ensure safe operation.

5. Operator Training

Provide comprehensive training for crane operators to ensure they understand proper operating procedures and safety protocols.

Choosing the Right Gantry Crane

Selecting the right gantry crane for your needs involves considering several factors:

1. Load Capacity

Determine the maximum weight the crane needs to lift and select a crane with an appropriate load capacity.

2. Span and Height

Consider the span (the distance between the crane's legs) and the height of the lift required for your operations.

3. Mobility

Decide if you need a stationary crane or a portable one that can be moved around your facility.

4. Environment

Consider the environment in which the crane will operate. Outdoor cranes should be weather-resistant, while indoor cranes may need to navigate around existing structures.

5. Customization

Look for manufacturers that offer customization options to tailor the crane to your specific requirements.

Conclusion

Gantry cranes are economical, effective, and adaptable lifting and material handling equipment used in a variety of industries. Businesses may optimize their operational efficiency and guarantee safe and dependable performance by knowing the many kinds of gantry cranes, their uses, advantages, and maintenance needs.

Purchasing the appropriate gantry crane can revolutionize your operations, increase output, and boost security. Gantry cranes may boost your operations to new heights in any industry, including manufacturing, transportation, construction, and storage. Accept the influence of gantry cranes and witness the transformation of your manufacturing processes.