In today’s fast-paced packaging industry, efficiency, reliability, and precision define success. Every manufacturer, distributor, and logistics company needs packaging solutions that not only secure products but also enhance productivity. One of the most essential tools driving this change is the strapping machine.

Strapping machines have become an integral part of modern packaging operations — and brands like Bandma are leading the way by offering advanced, user-friendly, and cost-effective solutions that fit businesses of every scale.

Let’s dive into everything you need to know about strapping machines — from how they work to why they’re crucial for your packaging line.

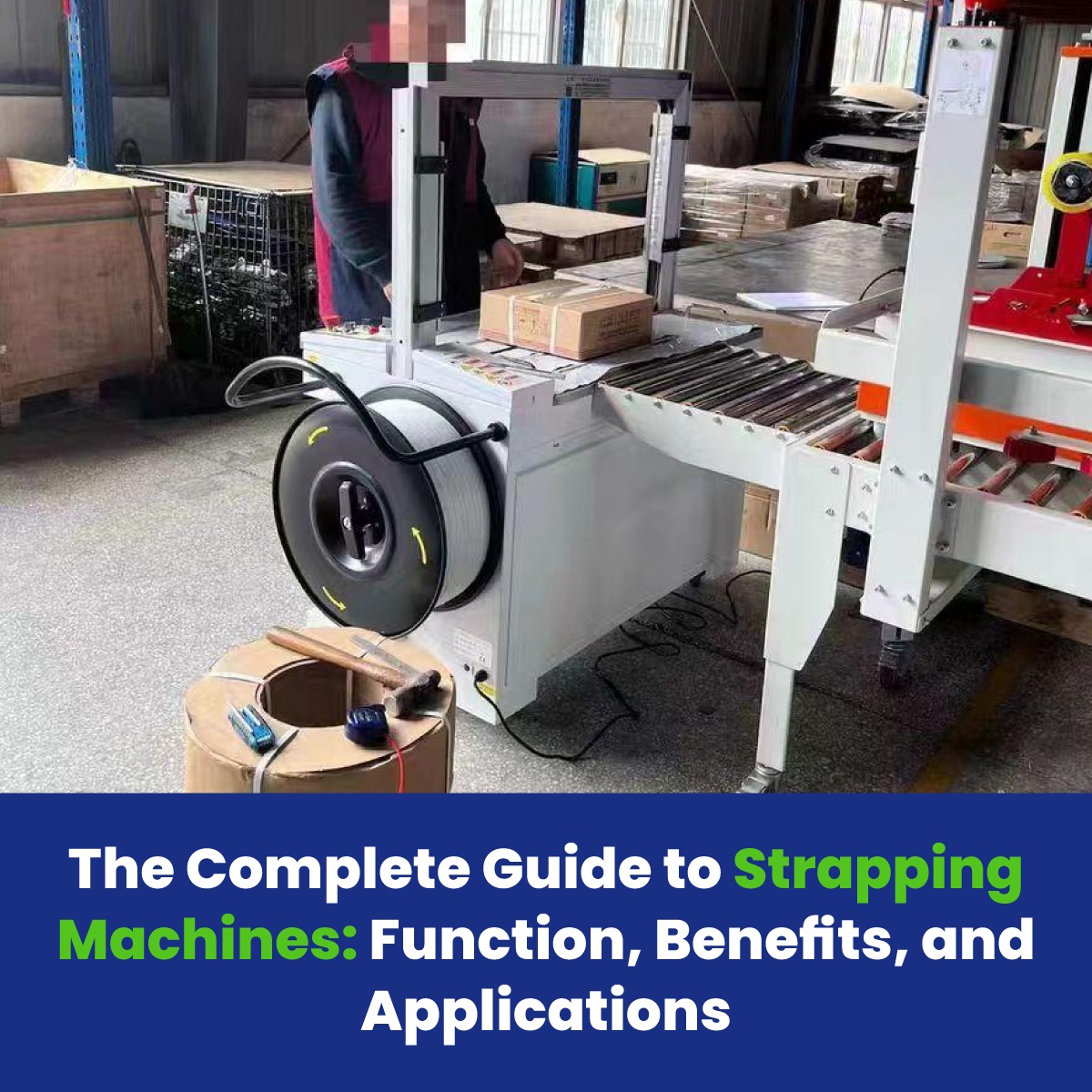

1. What Is a Strapping Machine?

A strapping machine is a packaging device that secures bundles, boxes, or pallets using a plastic or steel strap. The strap wraps around the product or package to hold it tightly in place during handling, storage, or transportation.

This simple yet powerful mechanism ensures that goods remain stable and undamaged throughout the supply chain.

Bandma’s strapping machines are designed to handle various materials like PP (Polypropylene) and PET (Polyester) straps — offering strong, reliable seals for different load types and industries.

2. How Does a Strapping Machine Work?

While the mechanism may seem complex, the process is straightforward. A strapping machine automatically:

- Feeds the strap around the package.

- Tensions it to the desired tightness.

- Seals the strap (using heat, friction, or ultrasonic welding).

- Cuts off the excess strap.

This entire process takes just a few seconds, ensuring consistency and speed that manual strapping can’t match.

Bandma’s Automatic and Semi-Automatic Strapping Machines use smart sensors and precision control systems for accurate tension and reliable sealing — ensuring each package is perfectly secured every time.

3. Types of Strapping Machines

Depending on your production volume, product size, and packaging speed, strapping machines come in different models.

a) Manual Strapping Machines

Used for low-volume operations, these require some manual effort to tension and seal the strap.

b) Semi-Automatic Strapping Machines

Ideal for small and medium businesses. Operators insert the package, and the machine automatically tensions, seals, and cuts the strap. Bandma’s Semi-Automatic Strapping Machines are compact, easy to use, and highly efficient for everyday packaging needs.

c) Fully Automatic Strapping Machines

These are integrated into production lines for high-speed operations. The machine automatically detects the package, applies the strap, and seals it — no manual intervention needed.

Bandma’s Automatic Strapping Machines deliver unmatched consistency and productivity, making them ideal for manufacturing, logistics, and e-commerce warehouses.

4. Key Benefits of Using a Strapping Machine

1. Enhanced Product Security

Proper strapping prevents packages from shifting or opening during transport. Bandma machines maintain precise tension, ensuring tight, uniform straps every time.

2. Improved Efficiency and Speed

Manual strapping can take minutes; Bandma’s machines complete it in seconds. This boosts output and reduces labor costs significantly.

3. Professional Packaging Appearance

Neat, uniform strapping gives products a clean and professional look building trust and brand value.

4. Reduced Material Waste

Automated control ensures optimal strap usage, saving material and lowering costs.

5. Lower Labor Dependency

Automation reduces manual effort and training requirements, letting your team focus on other key operations.

6. Consistency and Accuracy

Bandma machines are equipped with PLC-based systems that maintain precise strap tension and sealing temperature, ensuring consistent quality across every package.

5. Applications of Strapping Machines

Strapping machines are widely used across industries to bundle, secure, and stabilize products for storage and transport.

Here are some major sectors that rely on them:

- Logistics & Warehousing: For palletizing, carton sealing, and shipment packaging.

- Food & Beverages: Securing cartons and crates of bottles, cans, or packets.

- Pharmaceuticals: Ensuring product stability and tamper-proof packaging.

- E-commerce & Retail: For packaging goods quickly and safely during order fulfillment.

- Manufacturing & Engineering: Bundling components, raw materials, or finished goods for safe handling.

Bandma’s strapping machines are engineered to meet the diverse needs of all these industries, offering tailored solutions for both light and heavy-duty applications.

6. Why Choose Bandma Strapping Machines?

Bandma has been a trusted name in the packaging industry for over three decades — known for innovation, quality, and reliability. Here’s what makes Bandma’s strapping machines stand out:

- Precision Technology: Smart sensors and PLC controls ensure accuracy and performance.

- Durability: Built with high-quality materials to handle continuous operations.

- Energy Efficiency: Designed to reduce power consumption while maintaining output.

- Easy Maintenance: User-friendly design with easily available spare parts and technical support across India.

- Customization: Machines can be tailored to specific industry needs and production setups.

From small enterprises to large manufacturing units, Bandma offers strapping machines that fit every scale and budget.

7. The Future of Strapping: Smarter, Greener, and Faster

As packaging continues to evolve, so does strapping technology. Bandma is integrating IoT and AI-based monitoring systems that enable predictive maintenance, remote tracking, and performance optimization.

These innovations not only improve efficiency but also support eco-friendly packaging by minimizing waste and energy use — aligning with the global push for sustainability.

Conclusion

A strapping machine is more than just a tool — it’s a productivity multiplier. It ensures your products are secure, your packaging is professional, and your operations run faster and smoother.

With Bandma’s advanced strapping machines, businesses of all sizes can achieve the same level of precision and efficiency as large manufacturers — at an affordable cost.

Whether you’re an SME looking to upgrade or an enterprise scaling production, Bandma’s range of Automatic and Semi-Automatic Strapping Machines offers the perfect blend of performance, reliability, and value.