The requirement for dependable, effective, and consistent strapping solutions is critical in the industrial packaging industry. Even little packing errors can result in product loss, higher expenses, and unhappy customers in high-volume operations. The Parallel Side Sealing Strapping Machine is a potent tool that has revolutionized packing efficiency for companies in a variety of industries. The foundation of contemporary packaging lines, this machine is built for accuracy and longevity and provides unmatched speed, stability, and consistency.

We'll go over the special advantages of parallel side sealing strapping machines in this article, as well as how they work in high-volume packing and why getting one could revolutionize your company.

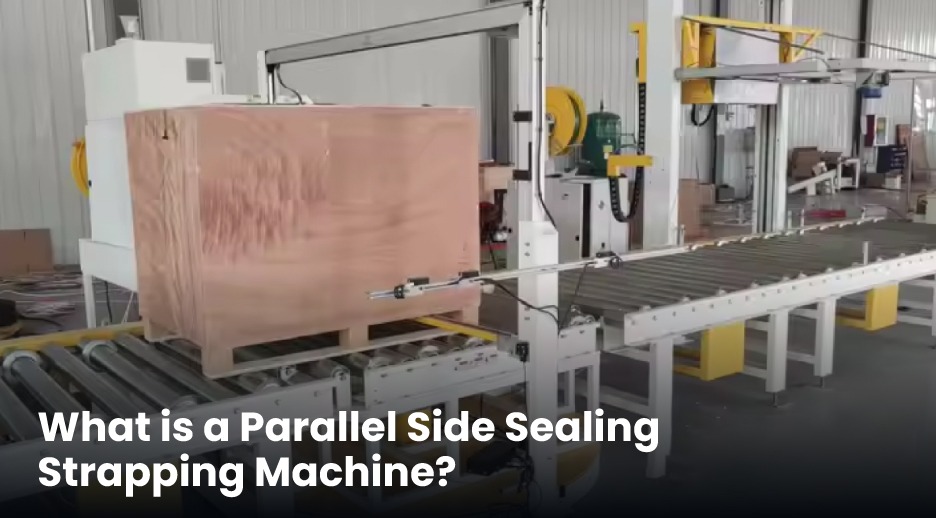

1. What is a Parallel Side Sealing Strapping Machine?

A sophisticated piece of machinery designed especially to apply strapping around objects with parallel side seals is a parallel side sealing strapping machine. Parallel side sealing machines provide more flexibility and stability than typical machines that might use top or bottom seals, particularly for products with enormous dimensions, hefty weights, or irregular forms. In order to secure items during handling and transportation, these devices make sure that the strapping is done accurately and securely.

Typically, parallel side sealing strapping machines are used in industries such as:

- Warehousing and logistics

- Automotive parts packaging

- Appliances and electronics

- Furniture and construction materials

2. Key Advantages of Parallel Side Sealing Strapping Machines

For high-volume packaging processes, parallel side sealing strapping machines are perfect because of their many advantages. The following are some of the main benefits that distinguish them from alternative strapping options:

A. Consistent Tension and Secure Sealing

Because of its design, the machine can keep the strapping tension constant for a wide range of package weights, sizes, and types. By ensuring that objects are firmly strapped, this constant tension reduces the possibility of shifting, damage, or spilling while in transit. Product stability is further improved by the secure side sealing, particularly for large or irregularly shaped packages.

B. Enhanced Speed and Efficiency

Because they are designed to operate at high speeds, parallel side sealing strapping machines are appropriate for establishments with high throughput needs. These devices significantly cut down on the amount of time required to get packages ready for shipping by automating the strapping process, enabling companies to boost productivity without sacrificing quality.

C. Adaptable for Different Package Types

These machines can handle a wide range of product shapes, including oddly shaped items and boxes and cartons. Businesses that deal with a variety of product lines can particularly benefit from this adaptability. Every product, regardless of size or shape, is guaranteed to be securely strapped thanks to the parallel side sealing feature.

D. Durability and Low Maintenance

Usually constructed of sturdy materials that can tolerate continuous operation, parallel side sealing strapping machines are intended for industrial application. Because they are long-lasting and require little upkeep, they are an affordable long-term investment. Additionally, a lot of contemporary models have automated maintenance warnings, which make it simple for operators to keep an eye on and maintain the machine.

E. Reduced Material Waste

These devices aid in minimizing material waste by applying the ideal tension and strap length for every item. By reducing plastic usage and waste, effective strapping material utilization not only reduces package costs but also supports environmental objectives.

3. How Parallel Side Sealing Strapping Machines Support High-Volume Packaging Success

For businesses handling thousands of packages daily, speed and consistency are critical. Parallel side sealing strapping machines enable companies to maintain a seamless flow of packaged products while adhering to stringent quality standards. Here’s how they contribute to high-volume packaging success:

A. Seamless Integration into Production Lines

Because parallel side sealing machines are made to work with automated production lines, they may be seamlessly incorporated into an existing workflow. By guaranteeing a seamless and uninterrupted packing process with minimal to no downtime, this integration raises overall productivity.

B. Reducing Labor Costs with Automation

A parallel side sealing strapping machine automates a large portion of the strapping procedure. In addition to expediting the process, this automation lessens the need for manual labor, freeing up workers to concentrate on other crucial production line activities. A smaller, more effective operation that lowers labor costs without compromising output quality is the end outcome.

C. Consistency in Large Batch Packaging

Even little discrepancies might cause serious operational problems when handling large volumes. In big quantities, parallel side sealing strapping machines guarantee consistent strapping quality, decreasing errors and lowering the possibility of product rejections or damage during transit.

D. Increased Operational Safety

These devices remove the need for hand strapping, which can lower the risk of workplace accidents, thanks to automated tension control and dependable side sealing. To further guarantee operator safety, several versions additionally have safety measures such protective covers and emergency stop buttons.

4. Key Features to Look For in a Parallel Side Sealing Strapping Machine

When considering an investment in a parallel side sealing strapping machine, certain features can help maximize your return on investment:

- Adjustable Tension Control: Allows you to customize the strapping tension for different package types, ensuring a secure fit without damaging the product.

- User-Friendly Interface: Look for machines with intuitive controls or touchscreen interfaces to simplify operator training and minimize errors.

- High-Speed Strapping: For high-volume operations, opt for machines with a high strapping rate per minute, which can significantly increase throughput.

- Compact Design: If floor space is a consideration, look for models that offer a compact design without compromising functionality.

- Energy Efficiency: Choose models with energy-saving features to help reduce operating costs over time.

5. Why Investing in a Parallel Side Sealing Strapping Machine is a Smart Choice

Purchasing a parallel side sealing strapping machine can help you make sure that your products arrive at consumers' locations in ideal shape in addition to boosting productivity. Consistent packaging is essential to attaining consumer satisfaction in today's cutthroat industry. Here are some reasons why purchasing this kind of machine is a wise decision:

- Improved Customer Satisfaction: Secure, consistent packaging reduces the risk of damage, ensuring that your products arrive safely and in pristine condition.

- Cost Savings Over Time: The machine's longevity, efficiency, and less material waste translate into long-term cost benefits, even though the original investment may be larger.

- Enhanced Brand Image: By putting in place superior automated packaging solutions, you show clients and partners that your company is dedicated to quality and creativity.

Conclusion

An essential tool for companies that specialize in producing high-volume, premium packaging is the parallel side sealing strapping machine. This machine makes sure that your packing process is successful by being reliable, quick, and capable of handling a variety of items. This technology is a crucial instrument in the quest for operational excellence since it allows businesses to increase customer happiness, cut expenses, and increase productivity.

Whether you are a logistics company, distributor, or manufacturer, a parallel side sealing strapping machine can be the secret to advancing your packaging business. Take advantage of the benefits of safe, effective, and dependable packaging by incorporating one into your manufacturing line.