In the modern, fast-paced industrial and logistics industries, productivity and efficiency are not only desired, but also necessary. As companies work to save expenses while meeting increasing demands, material handling system innovation has emerged as a top concern. Presenting telescoping conveyors, a revolutionary technology that offers unparalleled efficiency, flexibility, and safety while completely redefining loading and unloading processes.

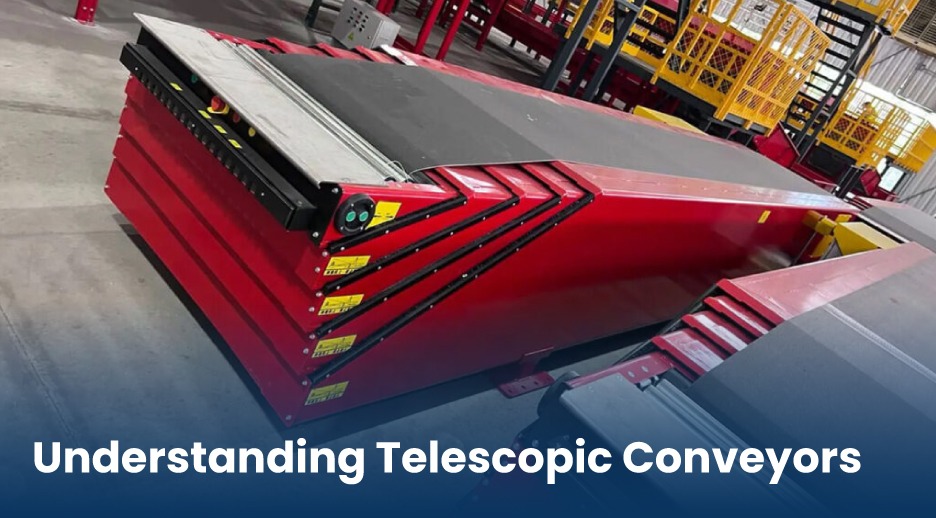

Understanding Telescopic Conveyors

A telescoping conveyor is a multipurpose piece of machinery that can be extended and retracted, making it the ideal instrument for loading and unloading products straight into or out of trucks, storage spaces, or containers. Because of its extendable portions, it can reach deep into trailers, doing away with the need for manual handling and greatly cutting down on turnaround times.

In sectors where accuracy and speed are critical, such manufacturing, distribution, warehousing, and e-commerce, telescopic conveyors are commonly employed.

Key Features of Telescopic Conveyors

Telescopic conveyors are equipped with features that make them indispensable for material handling:

- Extendable Sections

The telescoping design of the conveyor provides operational flexibility by enabling portions to expand and retract. - Adjustable Height

A lot of telescopic conveyors have height-adjustable mechanisms that allow them to be adjusted to different trailer or dock heights. - Ease of Operation

With simple controls for extension, retraction, and speed adjustment, these conveyors are usually easy to use. - Durable Construction

Telescopic conveyors can manage large loads and endure the demands of industrial use because they are made of sturdy materials. - Safety Features

They guarantee operator safety while in use thanks to their ergonomic designs, emergency stop buttons, and anti-collision sensors.

How Telescopic Conveyors Revolutionize Material Handling

1. Enhanced Productivity

Conventional loading and unloading techniques need a lot of manual labor, which slows down operations and raises labor expenses. A large portion of this labor is automated by telescopic conveyors, which enables operators to transport goods more rapidly and effectively. This leads to higher throughput and quicker turnaround times.

2. Reduced Labor Costs

Telescopic conveyors eliminate the need for a big crew in loading docks by reducing manual handling. In addition to saving money, this frees up labor for other crucial duties.

3. Improved Ergonomics and Safety

Accidents and repetitive strain injuries might result from manual loading and unloading. By lessening the physical strain on employees, telescopic conveyors help to mitigate these risks. Their cutting-edge safety measures and ergonomic design make the workplace safer.

4. Optimized Space Utilization

When retracted, telescopic conveyors take up little room in warehouses and loading docks. They are perfect for businesses with limited space because of their flexibility to extend inside trucks or containers, which maximizes the use of available space.

5. Versatility Across Industries

Telescopic conveyors can handle a variety of products, such as packages, cartons, tires, and more, in industries ranging from retail and e-commerce to automotive and pharmaceuticals. They are a flexible option for companies with a range of material handling requirements due to their versatility.

Applications of Telescopic Conveyors

Telescopic conveyors have become a critical tool in various industries:

- E-Commerce and Retail

E-commerce requires high-speed operations. Telescopic conveyors provide for quicker loading and unloading, which expedites order fulfillment. - Warehousing and Distribution

By moving goods straight from storage rooms to transport vehicles, these conveyors increase warehouse efficiency. - Automotive

Telescopic conveyors make it simple to move heavy products, including tires and engine parts, while maintaining efficiency and safety. - Food and Beverage

Telescopic conveyors are perfect for moving packaged food and drink items because of their hygienic designs. - Pharmaceuticals

In this sector, accuracy and caution are essential, and telescoping conveyors offer the dependability required for delicate goods.

The Role of Technology in Telescopic Conveyors

Telescopic conveyors are not just mechanical solutions—they integrate advanced technologies that enhance their performance:

- Automation: A lot of telescopic conveyors have automatic features that eliminate the requirement for continuous physical labor.

- Smart Sensors: By identifying obstacles and averting mishaps, sensors guarantee seamless functioning.

- Data Analytics: Data can be gathered by integrated systems to gradually increase productivity and streamline processes.

These technological advancements make telescopic conveyors a vital component of modern material handling systems.

Why Choose Bandma Telescopic Conveyors?

Bandma is a trusted name in the packaging and material handling industry, known for delivering innovative and reliable solutions. Our telescopic conveyors are designed to meet the demands of dynamic industries, offering:

- Customizable Designs: Tailored to suit your specific needs.

- Robust Performance: Engineered for heavy-duty usage.

- Comprehensive Support: From installation to maintenance, Bandma ensures seamless operations.

With Bandma’s telescopic conveyors, you can take your material handling processes to the next level.

Conclusion

Telescopic conveyors are a ground-breaking material handling solution in a time when speed and efficiency are crucial success factors. They are a great tool for companies looking to cut expenses and increase production because of their capacity to automate, optimize, and streamline loading and unloading processes.

Whether you work in manufacturing, warehousing, or e-commerce, telescopic conveyors may revolutionize your business processes and make your supply chain safer, quicker, and more effective.

Ready to revolutionize your material handling process? Contact Bandma today to learn how our telescopic conveyors can empower your business.