In the modern packaging industry, speed and consistency define success. As consumer demand rises and production timelines shrink, manufacturers across every sector are turning to automation to stay ahead. Among the most impactful innovations driving this change are case erector machines and at the forefront of this transformation is Bandma.

Bandma’s Case Erector Machines are engineered to automate one of the most time-consuming steps in the packaging process: forming and sealing cartons. By replacing manual handling with precision-driven automation, Bandma helps industries achieve faster, smarter, and more efficient packaging lines that deliver measurable results.

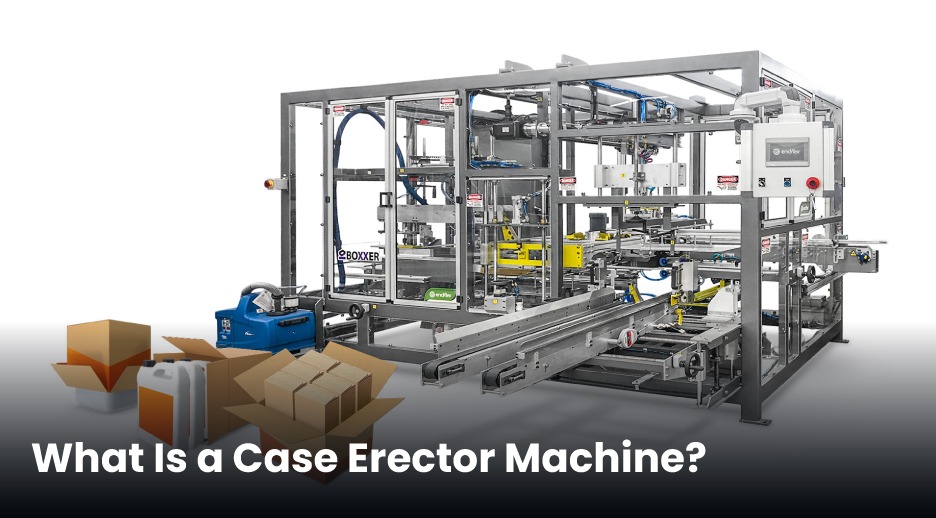

1. What Is a Case Erector Machine?

A case erector machine automatically takes flat cardboard blanks and transforms them into perfectly formed boxes, ready for filling and sealing.

In manual setups, workers must fold, shape, and tape each box — a repetitive and error-prone process that slows production. Bandma’s automated case erectors eliminate this inefficiency by handling the process with speed, accuracy, and uniformity.

The result: consistent carton quality, reduced labor dependency, and a seamless transition between packaging stages.

2. The Bandma Advantage

Bandma has built its reputation on precision engineering, reliability, and innovation. Its case erector machines are not just tools — they are complete automation solutions designed to integrate smoothly with existing packaging systems.

Here’s what makes Bandma stand out:

✅ High-Speed Operation

Bandma’s machines are capable of erecting dozens of cartons per minute, maintaining speed without compromising accuracy.

✅ Smart Automation Control

Equipped with PLC-based control panels, these machines offer real-time monitoring, easy programming, and quick adjustments making operation smooth and intuitive.

✅ Consistent Box Quality

Every carton is formed with identical precision, ensuring stability and uniform shape — critical for downstream packaging and sealing.

✅ Durability & Low Maintenance

Built with heavy-duty components and modular design, Bandma case erectors require minimal maintenance and deliver long-term reliability even under continuous operation.

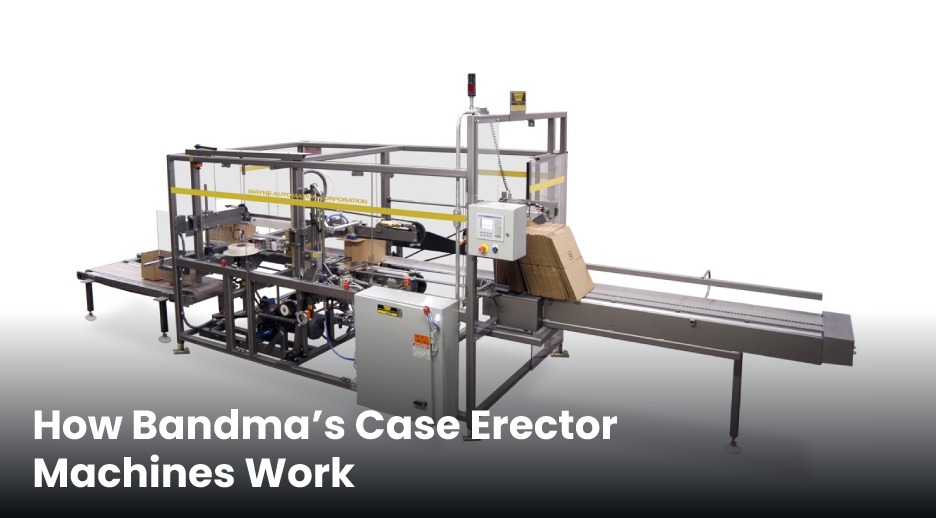

3. How Bandma’s Case Erector Machines Work

The process is simple yet incredibly efficient:

- Feeding – Flat carton blanks are loaded into a magazine.

- Erecting – The machine automatically picks, folds, and shapes each blank into a box.

- Sealing – The bottom flaps are sealed (taped or glued) automatically.

- Delivery – The formed case moves forward for filling or labeling.

Each step is executed using pneumatic arms, servo motors, and sensors, ensuring perfect alignment and flawless sealing without the need for manual correction.

4. Benefits of Using Bandma Case Erector Machines

1. Enhanced Productivity

With continuous, automated box formation, production lines move faster, minimizing idle time and increasing overall throughput.

2. Labor Optimization

By automating repetitive carton forming tasks, Bandma’s machines free up manpower for more skilled operations reducing labor fatigue and costs.

3. Precision and Consistency

Every carton is identical in shape and strength, reducing damage during filling and shipping.

4. Space and Cost Efficiency

Compact machine design and low operational costs make Bandma case erectors ideal for both large-scale plants and SMEs.

5. Safety and Ease of Operation

With user-friendly control panels and built-in safety sensors, the machines ensure safe and simple operation for every shift.

5. Applications Across Industries

Bandma’s Case Erector Machines are widely used in sectors where packaging quality and speed are essential:

- Food & Beverage Industry – For erecting boxes for bottles, cans, or packaged foods.

- E-commerce & Logistics – For consistent, high-speed carton setup in fulfillment centers.

- Pharmaceuticals & Healthcare – For precise, clean, and tamper-free packaging.

- Consumer Goods – For handling a wide variety of product sizes and box types.

- Industrial & Automotive – For durable carton formation in heavy-duty applications.

From corrugated cartons to custom box types, Bandma’s erectors can be customized to meet diverse production needs.

6. Integration with Smart Packaging Systems

As industries move toward Industry 4.0, Bandma is leading the way with intelligent case erecting technology.

Its advanced systems offer:

- IoT connectivity for performance tracking and remote monitoring.

- Predictive maintenance alerts to minimize downtime.

- Energy-efficient motors for sustainable operations.

- Modular design that allows easy integration with Bandma’s sealing, strapping, and wrapping machines.

This ensures manufacturers not only automate one part of their process but create a fully connected, data-driven packaging ecosystem.

7. Why Manufacturers Choose Bandma

The answer lies in three words: Trust, Technology, and Performance.

Manufacturers across India and abroad trust Bandma for:

- Proven reliability across thousands of installations.

- Tailored solutions designed for specific industry needs.

- End-to-end support from consultation to maintenance.

- Consistent ROI, thanks to reduced downtime and higher output.

With a focus on quality engineering and after-sales excellence, Bandma ensures every client experiences not just automation but transformation.

Conclusion

In today’s packaging world, speed and precision are everything. Manual processes can’t keep up with modern demand but Bandma’s Case Erector Machines ensure your operations do.

By automating carton forming and sealing, Bandma helps manufacturers save time, cut costs, and achieve consistent quality across every package.

For companies looking to future-proof their packaging lines, Bandma’s Case Erector Machines are not just an investment in automation they’re an investment in efficiency, reliability, and growth.

Because when packaging needs to move faster and smarter Bandma delivers.