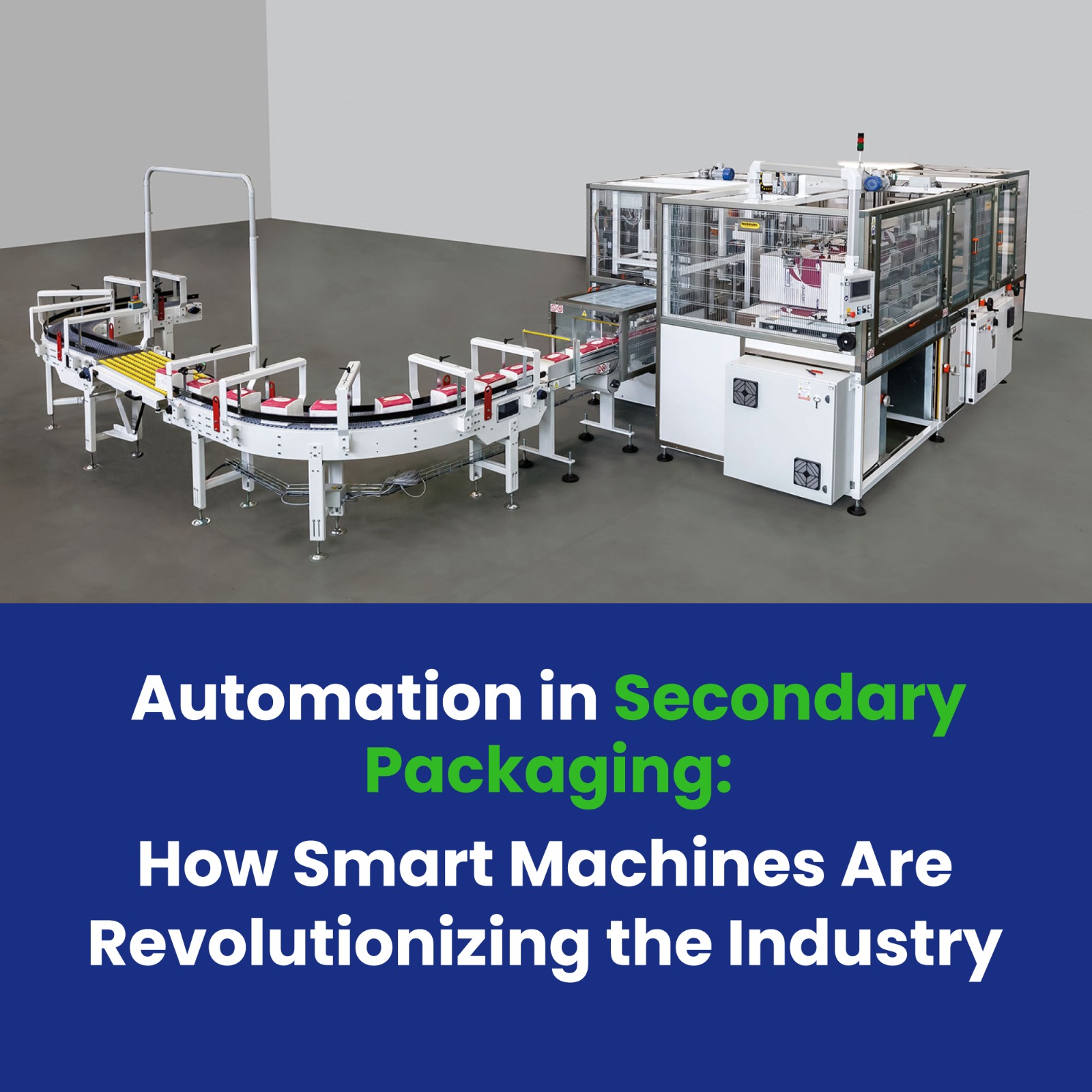

The introduction of automation and smart technologies is causing a rapid revolution in the packaging sector. Automated machines in secondary packaging are transforming activities where speed, accuracy, and efficiency are critical. Businesses may maintain consistency in packaging quality, cut expenses, and increase productivity by incorporating intelligent packaging solutions. In this field, Bandma provides advanced automation in secondary packaging to assist companies increase productivity and streamline processes.

revolution by bringing in advanced secondary packaging technologies that boost output and simplify processes.

The Role of Automation in Secondary Packaging

Automation in secondary packing is the process of handling, securing, and preparing goods for shipping and storage through the use of sophisticated machinery, robotics, and AI-driven systems. By replacing manual procedures, these solutions increase accuracy and efficiency while drastically lowering the need for human interaction.

Key Benefits of Automation in Secondary Packaging

1. Increased Efficiency and Speed

Compared to manual labor, automated packing machines work much more quickly. Packaging lines operate smoothly with high-speed operations thanks to machines like Bandma's carton sealers and strapping systems, which cut down on production time and boost throughput overall.

2. Consistency and Quality Control

Automated devices offer consistent wrapping, strapping, and sealing, removing human error and guaranteeing uniform packing standards. This is especially crucial for sectors that need accuracy and adherence to rules.

3. Cost Savings and Waste Reduction

Businesses can drastically reduce labor expenses and material waste by putting automated secondary packaging systems into place. Cost-effective packaging procedures are achieved through the optimization of material utilization by machines such as Bandma's shrink-wrapping and pallet-wrapping systems.

4. Improved Safety in Packaging Operations

Workplace accidents and repetitive strain injuries can result from manual packing handling. By relieving physical strain on employees, automation improves safety by freeing them up to concentrate on supervisory responsibilities rather than physically demanding duties.

5. Enhanced Scalability for Growing Businesses

Manual packaging techniques become ineffective as organizations grow. Bandma's automated secondary packaging solutions enable businesses to expand without interruption while preserving output quality.

Smart Machines Transforming Secondary Packaging

1. Carton Sealing Machines

The accurate and secure taping done by Bandma's automatic carton sealers guarantees that boxes stay intact throughout transportation. These devices increase productivity and decrease the need for human labor, which makes them indispensable for high-volume packing processes.

2. Strapping Machines

The automated strapping devices from Bandma effectively secure product bundles, minimizing damage while in transit. Their adjustable strapping and high tension offer strong protection for secondary packaging.

3. Shrink Wrapping Solutions

A crucial element of secondary packing is shrink wrapping. Bandma's shrink-wrapping machines ensure product stability and a polished appearance by providing tight and protective wrapping.

4. Pallet Wrapping Machines

Advanced stretch film technology is used by Bandma's pallet wrapping equipment to effectively secure loads during bulk transit. While offering strong defense against shipping dangers, these machines reduce material waste.

5. AI-Driven Smart Packaging Systems

Bandma is leading the way in smart packaging solutions that monitor packing efficiency, identify faults, and optimize processes in real time through the combination of AI and IoT. These technologies use data-driven insights to help firms increase productivity.

The Future of Automation in Secondary Packaging

The future of secondary packaging is centered around full automation, smart integration, and sustainable practices. Companies are adopting:

- Robotics for precision handling

- AI-based predictive maintenance to prevent machine downtime

- Eco-friendly packaging automation to reduce environmental impact

Bandma is at the forefront of this transformation, delivering cutting-edge automated secondary packaging solutions to industries worldwide.

Why Choose Bandma for Secondary Packaging Automation?

1. Industry Knowledge: With years of experience, Bandma has developed cutting-edge packaging solutions to meet the various demands of the industry.

2. Cutting-Edge Technology: To maximize packaging efficiency, our machines integrate automation powered by artificial intelligence.

3. Customizable Solutions: To meet certain company needs, Bandma provides customized packaging solutions.

4. Sustainability Focus: We guarantee economical and environmentally responsible packing processes with our solutions.

Conclusion

Automation is now required in secondary packing, not an option. Smart machines can help firms increase productivity, improve quality, cut expenses, and improve safety. With Bandma's automated secondary packaging solutions, businesses can embrace the next wave of packaging technology and maintain their competitive edge in the market.

Bandma, your partner in smart packaging solutions, is the company to rely for dependable, high-performance secondary packaging automation.