Introduction

In today’s fast-paced packaging industry, businesses can’t afford delays or errors in sealing cartons. The choice of a carton taping machine plays a major role in how quickly, safely, and cost-effectively products are packed. But when it comes to investing, one common question arises: Should you go for a semi-automatic taping machine or an automatic taping machine?

Both have their own advantages and suit different types of businesses. In this blog, we’ll break down the differences, highlight the pros and cons, and help you decide which option is the right fit for your packaging needs.

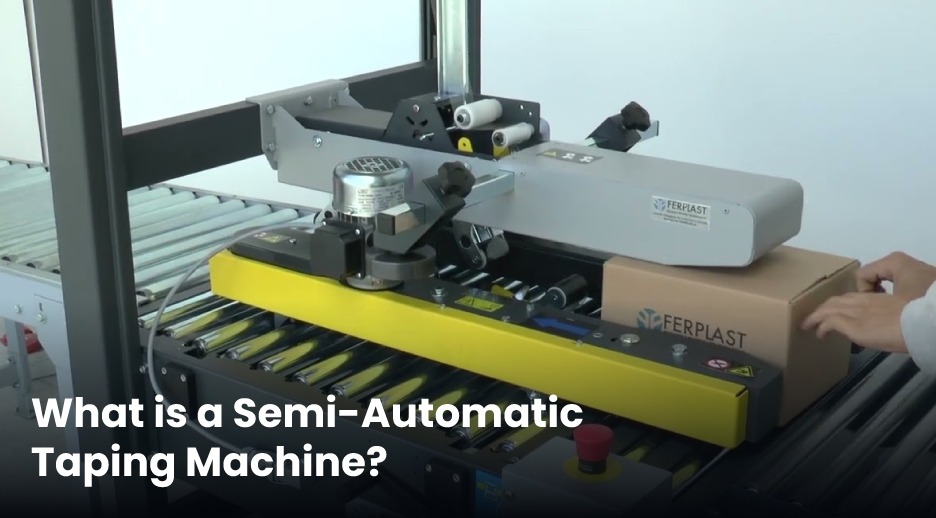

What is a Semi-Automatic Taping Machine?

A semi-automatic taping machine requires some manual assistance. The operator folds the top flaps of the carton, places it on the conveyor, and the machine applies tape to seal the top and bottom.

Where it works best:

- Small to medium businesses

- Low to medium packaging volume

- Industries with varied carton sizes that change frequently

Key Benefits:

- Affordable entry point

- Easy to operate with minimal training

- Flexible for different carton dimensions

- Compact size—fits even in smaller workspaces

Limitations:

- Depends on labor for consistent performance

- Slightly slower than automatic models

- Not ideal for high-volume production

What is an Automatic Taping Machine?

An automatic taping machine is designed for speed and efficiency. The operator simply feeds cartons onto the conveyor, and the machine automatically folds the top flaps, applies tape, and discharges the sealed box.

Where it works best:

- Large-scale warehouses and factories

- High-volume packaging operations

- Businesses looking to reduce labor dependency

Key Benefits:

- Consistent sealing quality at high speed

- Minimal manual involvement, saves labor cost

- Handles uniform carton sizes efficiently

- Integrates well with automated conveyor systems

Limitations:

- Higher upfront investment

- Best suited for businesses with steady, high-volume packaging

- Requires regular maintenance to perform at peak efficiency

Automatic vs Semi-Automatic: The Core Differences

Feature | Semi-Automatic Taping Machine | Automatic Taping Machine |

Operator Involvement | Manual flap folding + carton feeding | Minimal, cartons auto-fed & sealed |

Speed | Moderate (good for small batches) | High-speed (ideal for continuous runs) |

Carton Size Handling | More flexible with size variations | Best for uniform sizes |

Investment | Lower initial cost | Higher initial investment |

Best For | SMEs, startups, seasonal packaging | Large warehouses, e-commerce, FMCG hubs |

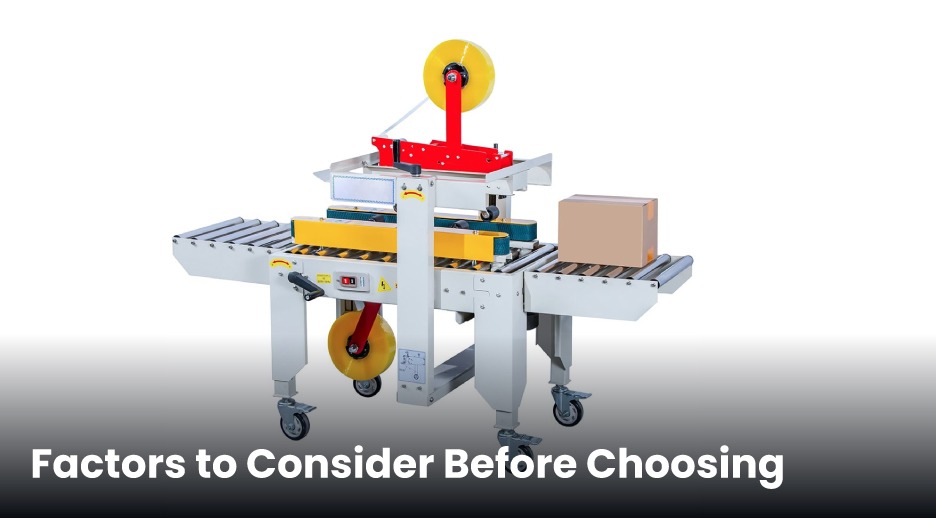

Factors to Consider Before Choosing

Packaging Volume

- If you’re sealing 100–300 cartons per day, a semi-automatic machine is sufficient.

- If you’re sealing 500–1000+ cartons per day, automatic machines provide better ROI.

- If you’re sealing 100–300 cartons per day, a semi-automatic machine is sufficient.

Carton Sizes

- For varying carton sizes, semi-automatic machines give more flexibility.

- For uniform carton sizes, automatic machines deliver speed and consistency.

- For varying carton sizes, semi-automatic machines give more flexibility.

Labor Costs

- Semi-automatic machines still require manpower.

- Automatic machines reduce dependency on labor and save long-term cost.

- Semi-automatic machines still require manpower.

Budget

- SMEs often start with semi-automatic due to the lower upfront investment.

- Enterprises with growth targets usually go for automatic models as they scale operations.

- SMEs often start with semi-automatic due to the lower upfront investment.

Long-Term ROI: Which One is Better?

While semi-automatic machines are more budget-friendly initially, businesses that experience steady growth and high shipping volume often find automatic machines more cost-effective over time. The reduced labor cost, consistent sealing, and faster output deliver a stronger return on investment (ROI).

Conclusion

Choosing between an automatic and semi-automatic taping machine depends on your business size, packaging volume, and long-term goals.

- Go for a Semi-Automatic Taping Machine if: you are a small to medium business, deal with varying carton sizes, and want a cost-effective solution to improve packaging speed.

- Go for an Automatic Taping Machine if: you run high-volume packaging operations, want to cut labor dependency, and need seamless integration with automated systems.

Investing in the right machine isn’t just about sealing cartons—it’s about improving efficiency, reducing costs, and scaling your operations with confidence.