When you see anything displayed on the shelves of a shop, showroom the first thing that attracts your attention is the label on the product. You will first pick up an item with attractive, catchy, luxurious, bright coloured labels. When you want to make, sell and offer products and services, the first most obvious step is to have a good and attractive label. Visual appeal is a very important factor for a business to attract customers.

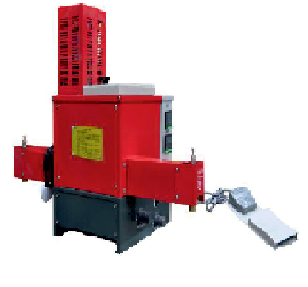

The best labeling machine will make your product labels good, attractive, luxurious and clear. These are very beneficial to the packaging industry as they use novel techniques and save time and money. Labeling machines paste printed labels on the finished products, containers, vials, ampoules, bottles, cartons and other packaging material. These are also known as labelers. The labels are self adhesive labels which have ready-made gum on the back side and it can be pasted easily on the container with little press by the labeling machine.

Labeling done manually is a very time consuming job and it is not a professional way of packing the product especially when bulk production is done. Using a labeling machine to package the products is time saving and more professional like a big packaging industry.

Labeling machines are used in pharmaceutical industries, consumer durable industries, FMCG and different types of packaging industries. Fully automatic with advanced features of labeling, these machines make your packaging job easy, hygienic, clean, and professional. You can also pick and choose from the range of labels and letters to customize the labels according to your requirement. Labeling machines are an important part of the chemicals, cosmetics, food and beverages, agriculture, electronics, pharmaceutical industry, etc. The labels give important information about the ingredients in the product, the manufacturing date, expiry date and information like quantity, list of features etc. Most of the machines have inbuilt self adhesive labeling systems for oval, cylindrical, flat and square containers. For barcode and overprint faults these machines have an auto reject facility.

Importance of Various Labeling Machines:

All types of labels have significance of their own and are important for various applications in different industries. For example, while a self adhesive labeling machine is important for attaching labels on the products, the shrink sleeve label applicator machines will shrink the labels tightly around the surface of the cylindrical products like bottles of different shapes with the help of heat. The labelers for attaching labels on different sides of the product are also available such as side labeling machines enabling labeling of the products on left and right sides while the back and front labeling machines are used for labeling the back and front facing sides of the object. There are even the wrap-around sticker labellers which are the best for wrapping the products with labels on all the sides while the top side labeling machines are employed for labeling the top parts of the products. Broadly classified the labeling machines today are available in automatic, semi automatic and fully automatic models.

Different types of Labeling Machines Available in Market:

Some commonly and widely labeling machines are available in the market which are Based on the different types, size and shapes of containers or vessels.

- Semi Automatic Labeling Machine used in small scale industries for labeling on round vials, bottles, syringes, cartridges,etc.

- Fully automatic labeling machine is used for labeling on front or back side of oval, plane, or square shaped goods bottles, cans, ampoules or vials as well as special formats such as pallets and cardboard boxes.

- High speed ampoule, vial sticker labeling machine is used to apply labels on ampoules, Round Ampoules, Vials, round objects.and other containers vertically at very high speed.

- Hologram, security label application machine is used as the security of hologram applicator and label applicator. It is fixed on the existing packaging line conveyors.

- Ampoule or vial labeling machine-horizontal is used for full or partial wrap around labeling on round containers with small diameter.

- Vial labeling machines are developed to handle most sticker applications with minimal human interference. It is used to label small, round shaped products like vials, ampoules, and test tubes.

Thus, labeling machines are durable, the low maintenance cost makes them more efficient, and it saves cost and money which in turn improves productivity of the packaging industry. Labeling machines are easy to operate and monitor.

Conclusion:

So, The Final Conclusion is that Labeling machines are very important for faster and efficient packaging processes in industries. This blog educates people about the importance of labeling machines in packaging processes and to provide information on different types of labeling machines available in the market.